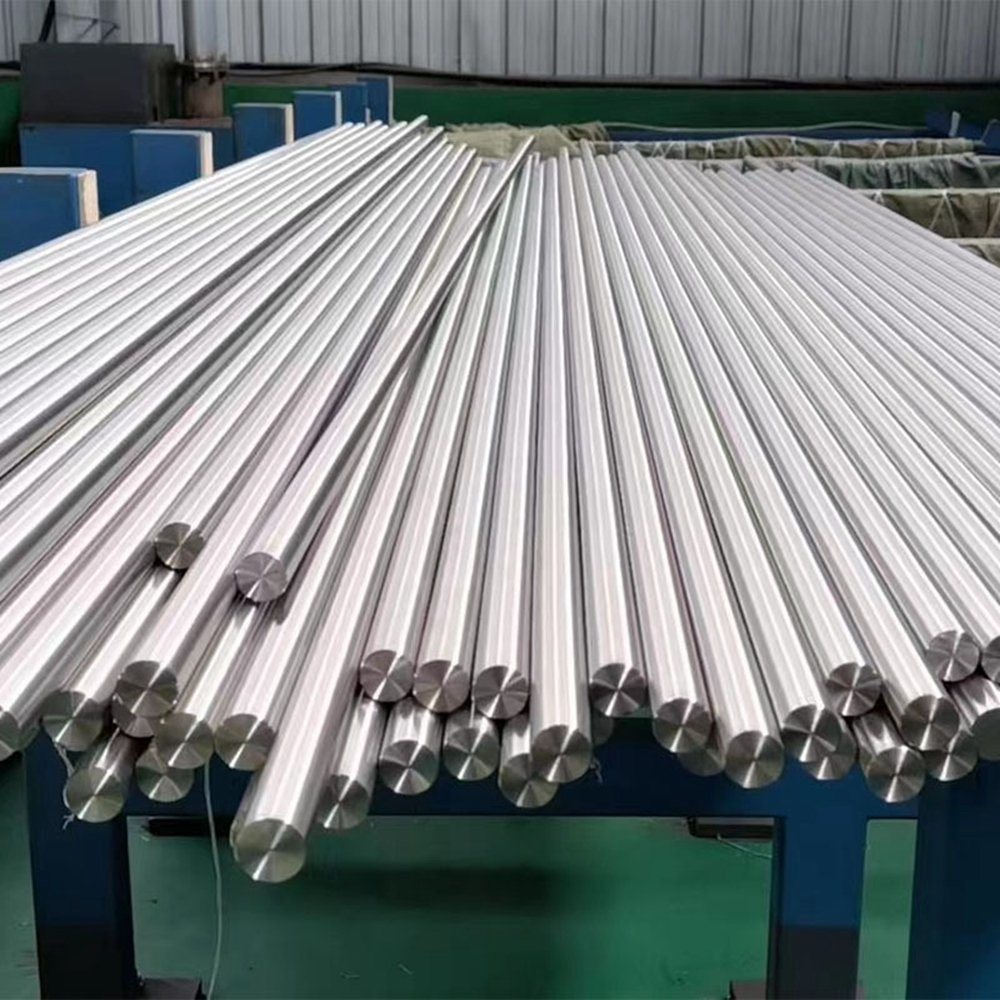

Inconel X-750 (UNS N07750) alloy is an age-hardenable, nickel-base superalloy with a very good strength at temperatures up to about 1600°F (870°C). It is widely used as a wrought material for forged and fabricated parts in aerospace and industrial applications. Its strength is somewhat less than that for Inconel 718 alloy up to about 1400°F (760°C), and lower than that for Inconel R-41 alloy at higher temperatures. Alloy X-750 can be cold-formed in the annealed condition, and may also be hot-formed at temperatures of about 1900°F (1040°C) or above. Weldability is somewhat limited by susceptibility to strain age-cracking under conditions of heavy restraint. The alloy exhibits good resistance to oxidizing combustion gas environments at temperatures up to about 1600°F (870°C).Inconel X750 Alloy Product Forms and Standards

Inconel X-750 (UNS N07750) alloy is an age-hardenable, nickel-base superalloy with a very good strength at temperatures up to about 1600°F (870°C). It is widely used as a wrought material for forged and fabricated parts in aerospace and industrial applications. Its strength is somewhat less than that for Inconel 718 alloy up to about 1400°F (760°C), and lower than that for Inconel R-41 alloy at higher temperatures. Alloy X-750 can be cold-formed in the annealed condition, and may also be hot-formed at temperatures of about 1900°F (1040°C) or above. Weldability is somewhat limited by susceptibility to strain age-cracking under conditions of heavy restraint. The alloy exhibits good resistance to oxidizing combustion gas environments at temperatures up to about 1600°F (870°C).Inconel X750 Alloy Product Forms and Standards | Bar | Forging | Sheet/Strip | Wire |

| ASTM B637 | ASTM B637 | AMS 5542 AMS 5598 | AMS 5698 AMS 5699 |

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 912 | 551 | 25 |

| Nickel: | 70 Balance |

| Chromium: | 16 |

| Iron: | 8 |

| Titanium: | 2.5 |

| Niobium* + Tantalum: | 1 |

| Aluminum: | 0.8 |

| Cobalt: | 1 max. |

| Manganese: | 0.35 max. |

| Silicon: | 0.35 max. |

| Carbon: | 0.08 max. |

| Test Temperature | Approximate Initial Stress to Produce Rupture in: | ||||||

| 10 h | 100 h | 1000 h | |||||

| °F | °C | ksi | MPa | ksi | MPa | ksi | MPa |

| 1100 | 600 | 120 | 825 | 85 | 585 | 71 | 490 |

| 1200 | 650 | 80 | 550 | 66 | 455 | 50 | 345 |

| 1300 | 705 | 61 | 420 | 45 | 310 | 29 | 200 |

| 1400 | 760 | 41 | 285 | 26 | 180 | 15 | 105 |

| 1600 | 815 | 24 | 165 | 14 | 97 | 7.4 | 51 |

| 1700 | 870 | 12.5 | 86 | 6.6 | 46 | - | - |

| 1800 | 925 | 6.5 | 45 | - | - | - | - |