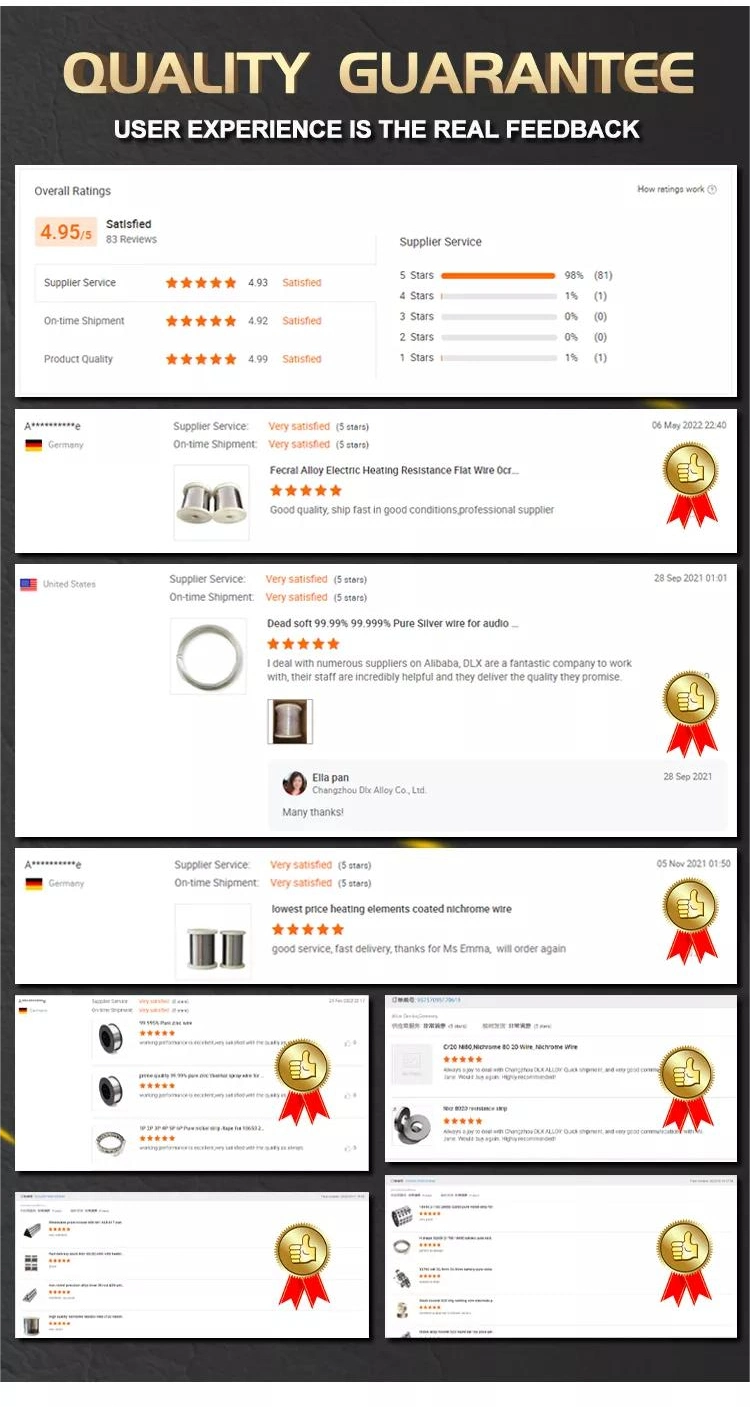

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate 1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy. Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.The properties of INCONEL alloy 690 are useful for various applications involving nitric or nitric/hydrofluoric acid solutions. Examples are tail-gas reheaters used in nitric acid production and heating coils and tanks for nitric/hydrofluoric solutions used in pickling of stainless steels and reprocessing of nuclear fuels. The alloy’s resistance to sulfur-containing gases makes it an attractive material for such applications as coal-gasification units, burners and ducts for processing sulfuric acid, furnaces for petrochemical processing, recuperators, incinerators, and glass vitrification equipment for radioactive waste disposal. In various types of high-temperature water, alloy 690 displays low corrosion rates and excellent resistance to stress-corrosion cracking. Thus, alloy 690 is widely used for steam generator tubes, baffles, tubesheets, and hardware in nuclear power generation. In addition to corrosion resistance, it features high strength and perfect fabrication properties. Such properties make this high performance nickel alloy suitable for heat transfer pipes of vapor generator in pressurized water reactor nuclear power plant. Specification of Inconel 690 Nickel Alloy

Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.The properties of INCONEL alloy 690 are useful for various applications involving nitric or nitric/hydrofluoric acid solutions. Examples are tail-gas reheaters used in nitric acid production and heating coils and tanks for nitric/hydrofluoric solutions used in pickling of stainless steels and reprocessing of nuclear fuels. The alloy’s resistance to sulfur-containing gases makes it an attractive material for such applications as coal-gasification units, burners and ducts for processing sulfuric acid, furnaces for petrochemical processing, recuperators, incinerators, and glass vitrification equipment for radioactive waste disposal. In various types of high-temperature water, alloy 690 displays low corrosion rates and excellent resistance to stress-corrosion cracking. Thus, alloy 690 is widely used for steam generator tubes, baffles, tubesheets, and hardware in nuclear power generation. In addition to corrosion resistance, it features high strength and perfect fabrication properties. Such properties make this high performance nickel alloy suitable for heat transfer pipes of vapor generator in pressurized water reactor nuclear power plant. Specification of Inconel 690 Nickel Alloy | UNS | W. Nr |

| N06690 | 2.4642 |

| Composition | Ni | Cr | Fe | C | Mn | Si | Cu | S | |

| Content(%) | Min. | 58.0 | 27.0 | 7.0 | 0.05 | ||||

| Max. | 31.0 | 11.0 | 0.5 | 0.5 | 0.5 | 0.015 | |||

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 580 | 260 | 30 |

| Bar | Forging | Sheet/Strip | Pipe |

| ASTM B166 | ASTM B564 | ASTM B168 | ASTM B163 ASTM B829 |