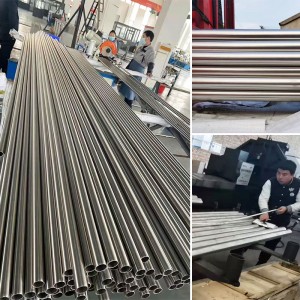

This alloy is a nickel-iron-chromium nickel-based corrosion-resistant alloy, which contains a small amount of metal elements molybdenum and copper. In reducing and oxidizing acids, it has good corrosion resistance, and good resistance to stress corrosion cracking, pitting and crevice corrosion. It has excellent corrosion resistance to sulfuric acid and phosphoric acid. This alloy has good cold and hot workability, easy cold forming and welding. The main products of this alloy are rods, pipes, plates, strips, wires and forgings, etc., which are mainly used in chemical, petrochemical, nuclear and rare metal refining industries. chemical composition(%) Ni(+Co)=38.0~46.0 Mo=2.5~3.5 Mn≤1.0 Al≤2.0 Fe≥22.0 Cu=1.5~3.0 S≤0.03 Ti=0.6~1.2 Cr=19.5~23.5 C≤0.05 Si≤0.5 physical constant Density (8.14Mg/m) Melting point (1370~1400°C) Specific heat (440J/Kg.°C) Resistivity (1.13μΩ.m) Executive standard Plate ASTM B424 Rod ASTM B425 Seamless pipe ASTM B423, ASTM B163

This alloy is a nickel-iron-chromium nickel-based corrosion-resistant alloy, which contains a small amount of metal elements molybdenum and copper. In reducing and oxidizing acids, it has good corrosion resistance, and good resistance to stress corrosion cracking, pitting and crevice corrosion. It has excellent corrosion resistance to sulfuric acid and phosphoric acid. This alloy has good cold and hot workability, easy cold forming and welding. The main products of this alloy are rods, pipes, plates, strips, wires and forgings, etc., which are mainly used in chemical, petrochemical, nuclear and rare metal refining industries. chemical composition(%) Ni(+Co)=38.0~46.0 Mo=2.5~3.5 Mn≤1.0 Al≤2.0 Fe≥22.0 Cu=1.5~3.0 S≤0.03 Ti=0.6~1.2 Cr=19.5~23.5 C≤0.05 Si≤0.5 physical constant Density (8.14Mg/m) Melting point (1370~1400°C) Specific heat (440J/Kg.°C) Resistivity (1.13μΩ.m) Executive standard Plate ASTM B424 Rod ASTM B425 Seamless pipe ASTM B423, ASTM B163

The Incoloy® alloys distributed by DLX are used in a wide range of industries and applications around the world, including: Aerospace Engineering Electrical Resistance Heating Oil and Gas Extraction Power Generation Automotive Engineering Electronics and Communications Petrochemical Processing Thermal Processing and Heat Treatment Chemical Processing Marine Engineering Pollution Control and Waste Processing Welding

The Incoloy® alloys distributed by DLX are used in a wide range of industries and applications around the world, including: Aerospace Engineering Electrical Resistance Heating Oil and Gas Extraction Power Generation Automotive Engineering Electronics and Communications Petrochemical Processing Thermal Processing and Heat Treatment Chemical Processing Marine Engineering Pollution Control and Waste Processing Welding