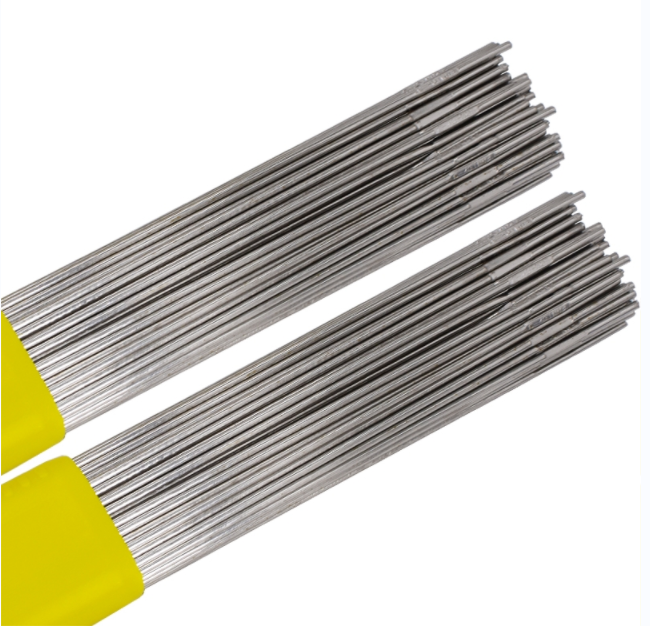

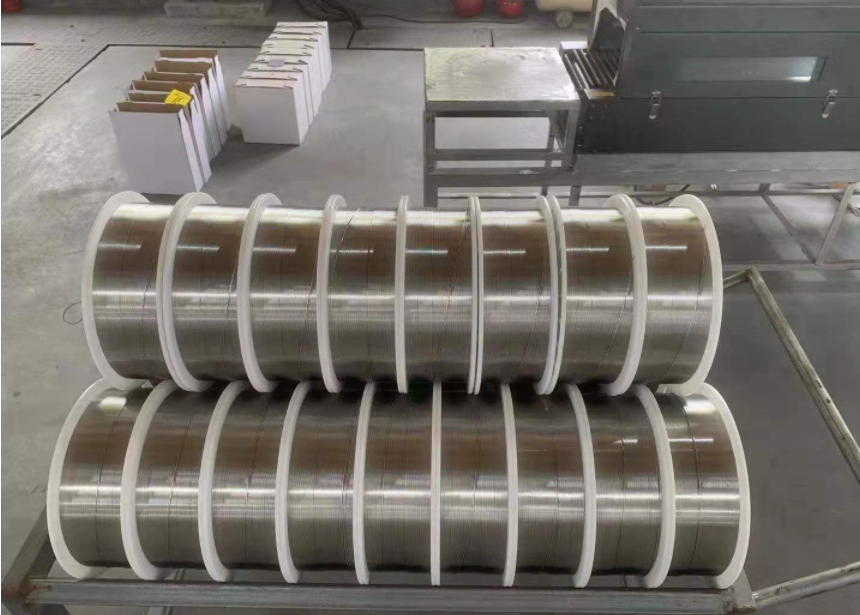

These welded wires are recurrently used in many industries, including chemical and petrochemical processing, oil and gas, power generation, pharmaceutical, pulp, paper production, and wastewater treatment.

These welded wires are recurrently used in many industries, including chemical and petrochemical processing, oil and gas, power generation, pharmaceutical, pulp, paper production, and wastewater treatment.| ERNiCrMo-4 Chemical Composition | |||||||||||||

| C | Mn | Fe | P | S | Si | Cu | Ni | Co | Cr | Mo | V | W | Other |

| 0.02 | 1 | 4.0-7.0 | 0.04 | 0.03 | 0.08 | 0.5 | Rem | 2.5 | 14.5-16.5 | 15.0-17.0 | 0.35 | 3.0-4.5 | 0.5 |

| ERNiCrMo-4 Mechanical Properties | |||||||||||||

| Tensile (psi) | 100,000 | ||||||||||||

| Mpa | 690 | ||||||||||||

| Elongation (%) | 30 | ||||||||||||