| C | Si | Mn | Cr | P | Ni | Ti | Co |

| ≤0.08 | ≤0.35 | ≤0.35 | 17.0-21.0 | ≤0.015 | 50.0-55.0 | 0.65-1.15 | ≤1.0 |

| Al | Mo | Fe | Cu | S | B | Nb+Ta | |

| 0.20-0.80 | 2.80-3.30 | Rem | ≤0.30 | <0.015 | ≤0.006 | 4.75-5.50 |

| Tensile Strength | 165,000 Psi | 1138 MPA |

| Elongation | 25-30% | |

| Density g/cm3 | 8.19 g/cm3 | |

| Melting Point ℃ | 1260-1335℃ | |

| Electrical Resistivity μΩ-m | 1.25 |

| Typical Welding Parameters | |||||

| Process | Diameter | Voltage | Amperage | Amperage | Gas |

| GTAW | 0.90mm | 12-15 | 60-90 | 30-40 CFH | 100% Argon |

| 1.20mm | 13-16 | 80-110 | 30-40 CFH | 100% Argon | |

| 1.60mm | 14-18 | 90-130 | 30-40 CFH | 100% Argon | |

| 2.40mm | 15-20 | 120-175 | 30-40 CFH | 100% Argon | |

| 3.20mm | 15-20 | 150-220 | 30-40 CFH | 100% Argon | |

| GMAW | 0.90mm | 26-29 | 150-190 | 30-50 CFH | 75% Argon + 25% Helium |

| 1.20mm | 28-32 | 180-220 | 30-50 CFH | 75% Argon + 25% Helium | |

| 1.60mm | 29-33 | 200-250 | 30-50 CFH | 75% Argon + 25% Helium | |

| SAW | 2.40mm | 29-32 | 300-350 | 30-50 CFH | Suitable Flux may be used |

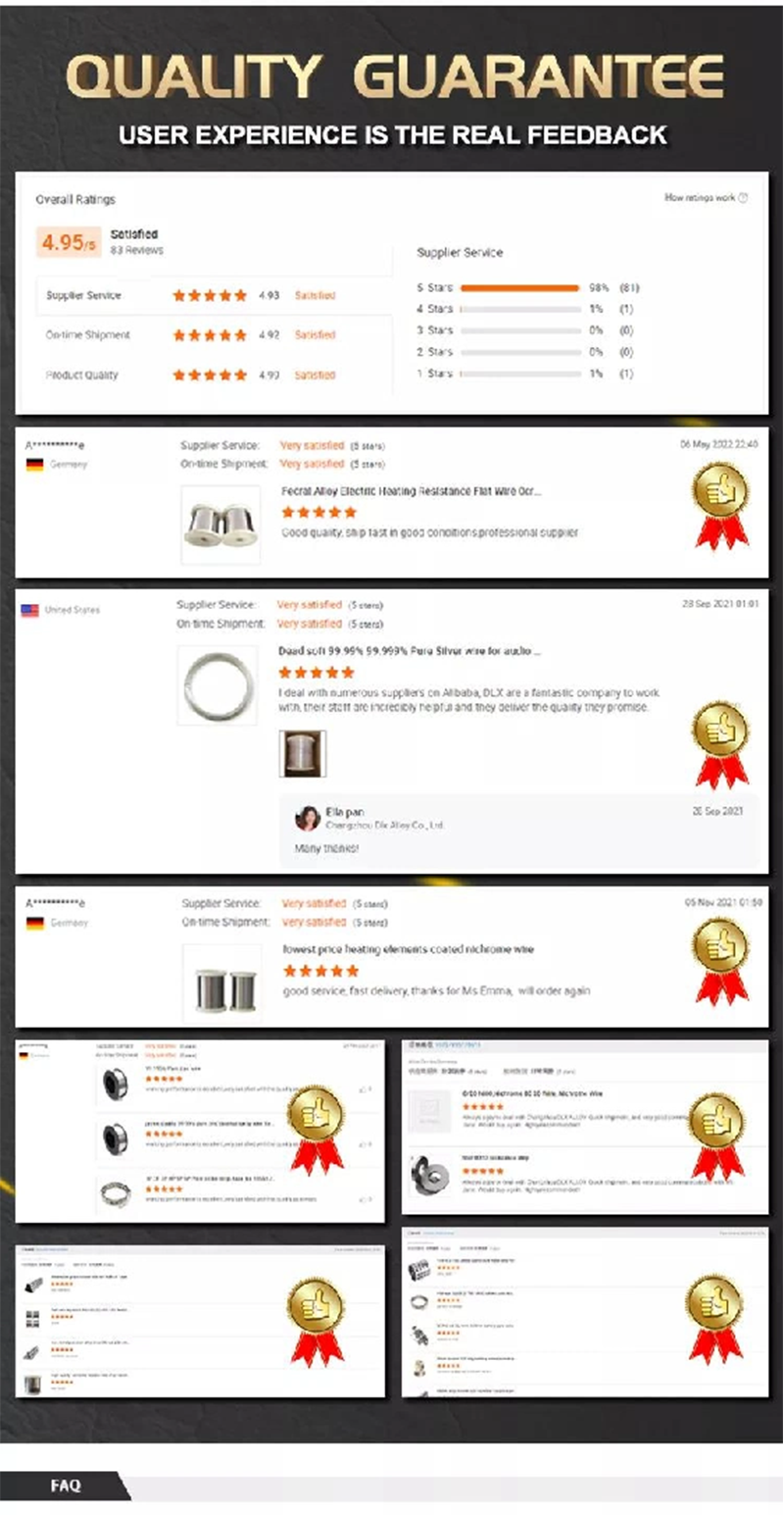

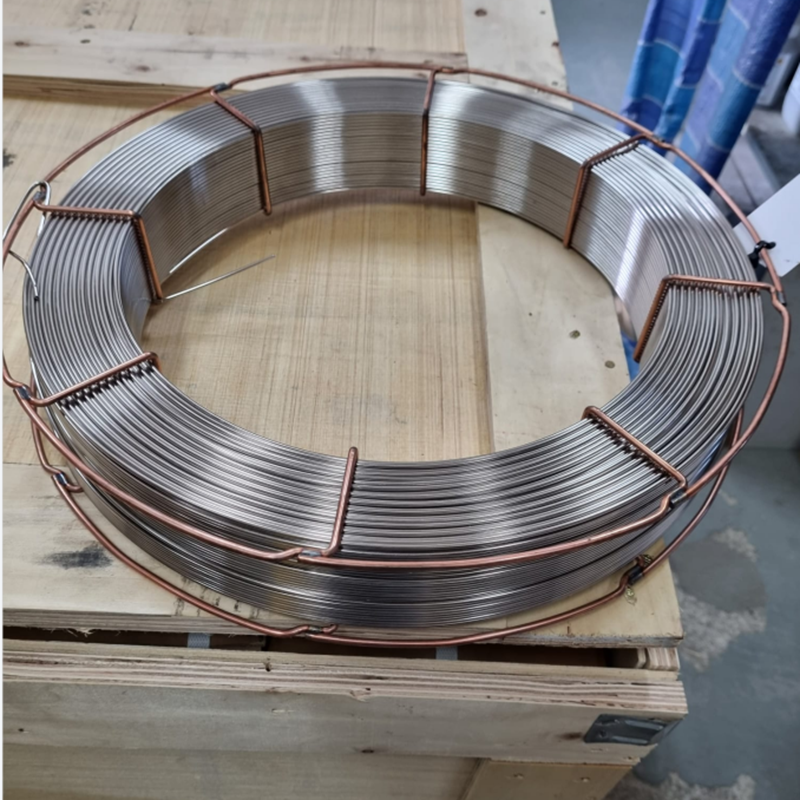

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate.

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate.

1. Raw material 2.Smelting 3.Drawing 4.Rolling 5.Annealing 6.Finished Product 7.Detection 8.Packing 9.Shipping

1. Raw material 2.Smelting 3.Drawing 4.Rolling 5.Annealing 6.Finished Product 7.Detection 8.Packing 9.Shipping

Question: Are you a trading company or manufacturer? Answer: We're manufacturer.

Question: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product?

Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome.

Question: Could you supply samples?

Answer: Yes, wecould supply samples according to your requirement.

Question: could we visit your factory?

Answer: Sure, factory visit is warmly welcome.