| ASTM B423 Alloy 825 Tubing Standards | ASTM B423/ ASME SB423, ASTM B705/ ASME SB705 UNS N08825 Tube |

| ASTM B423 Alloy 825 Seamless Tube Size | 3.35 mm OD To 101.6 mm OD |

| ASTM B423 Alloy 825 Welded Tube Size | 6.35 mm OD To 152 mm OD |

| ASTM B705 Incoloy 825 Tubing Swg & Bwg | 10 Swg., 12 Swg., 14 Swg., 16 Swg., 18 Swg., 20 Swg. |

| Inconel WERKSTOFF NR. 2.4858 Tube wall thickness | 0.020" –0.220", (special wall thicknesses available) |

| Inconel UNS N08825 Tubing Length | Single Random, Double Random, Standard & Cut length Tube |

| Inconel WERKSTOFF NR. 2.4858 Tubing Finish | Polished, AP (Annealed & Pickled), BA (Bright & Annealed), MF |

| Form | ‘U’ bent, Hollow, Hydraulic, LSAW, Boiler, Straight Tube, Tube Coil, Round, Rectangular, Square Etc |

| Types of 825 Alloy Tubing | Seamless, ERW, EFW, Welded, Fabricated Tube / Tubing |

| 825 Alloy Tube End | Plain End, Beveled End, Treaded Tube |

| Marking | All ASTM B423 Incoloy 825 Tubing are marked as follows: Standard, Grade, OD, Thickness, Length, Heat No. (Or according to the customer’s request.) |

| Application & uses of Incoloy 825 Tube | Oil Tube, Gas Tube, Fluid Tube, Boiler Tube, Heat exchanger Tube, |

| Value Added Service | Draw & Expansion as per required Size & Length, Polish (Electro & Commercial) Annealed & Pickled Bending, Machining Etc. |

| Specialize in | ASTM B423 Incoloy 825 Capillary Tube & Other Odd Size Inconel NCF 825 Heat Exchanger & Condenser Tube |

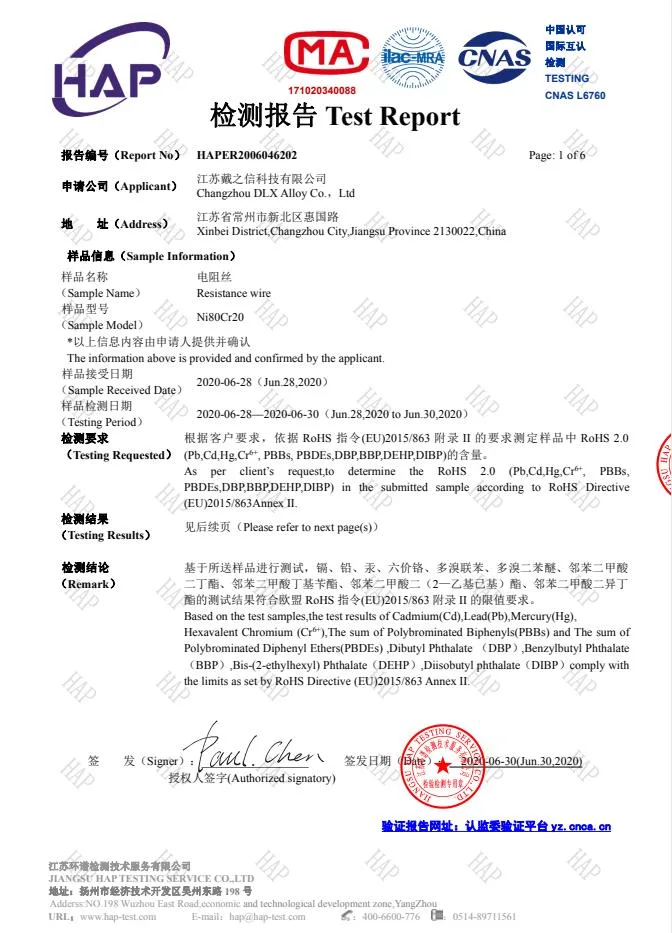

| Test Certificate | Manufacturer Test Certificate Laboratory Test Certificate from Govt. Approved Lab. Under Third Party Inspection |

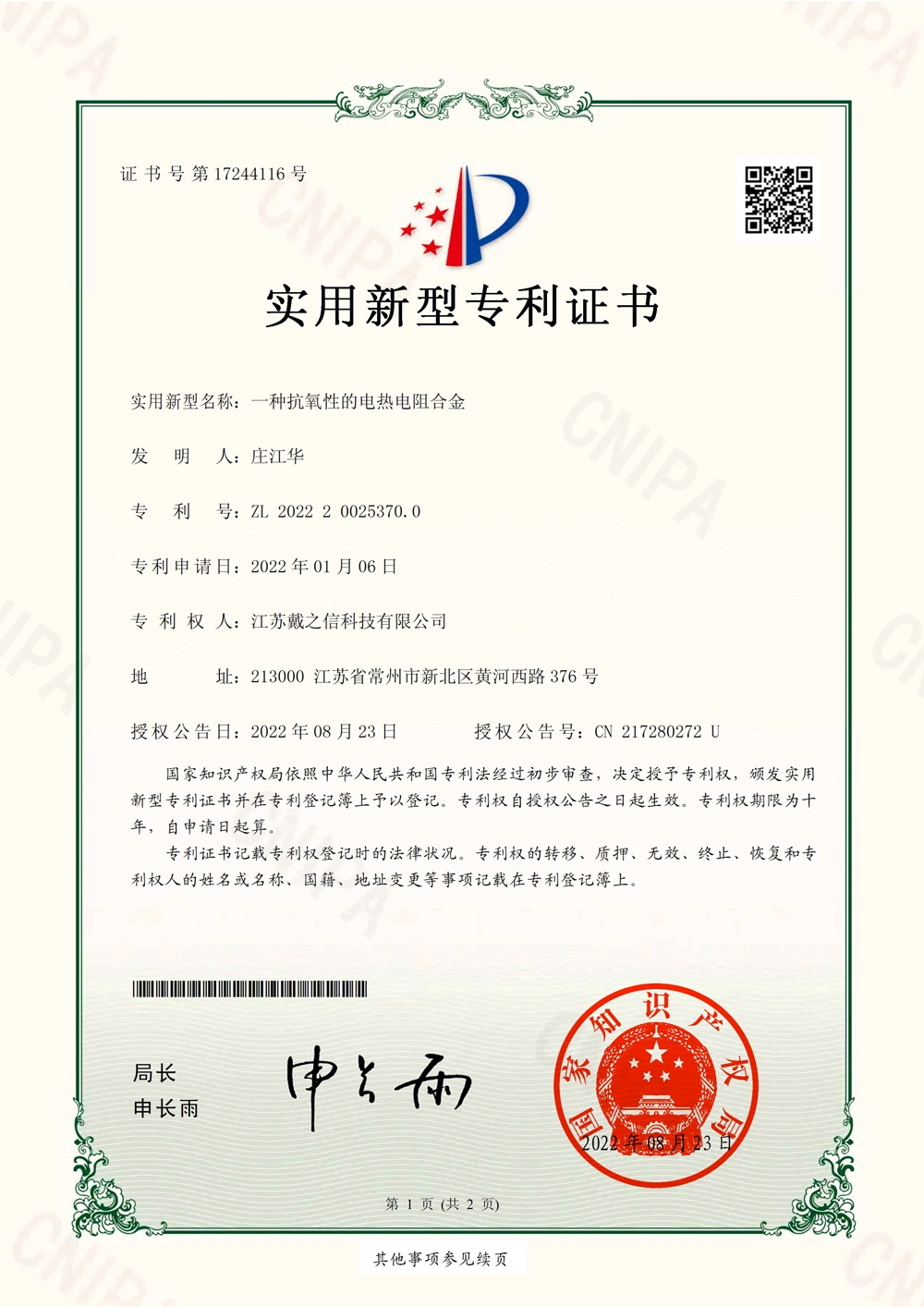

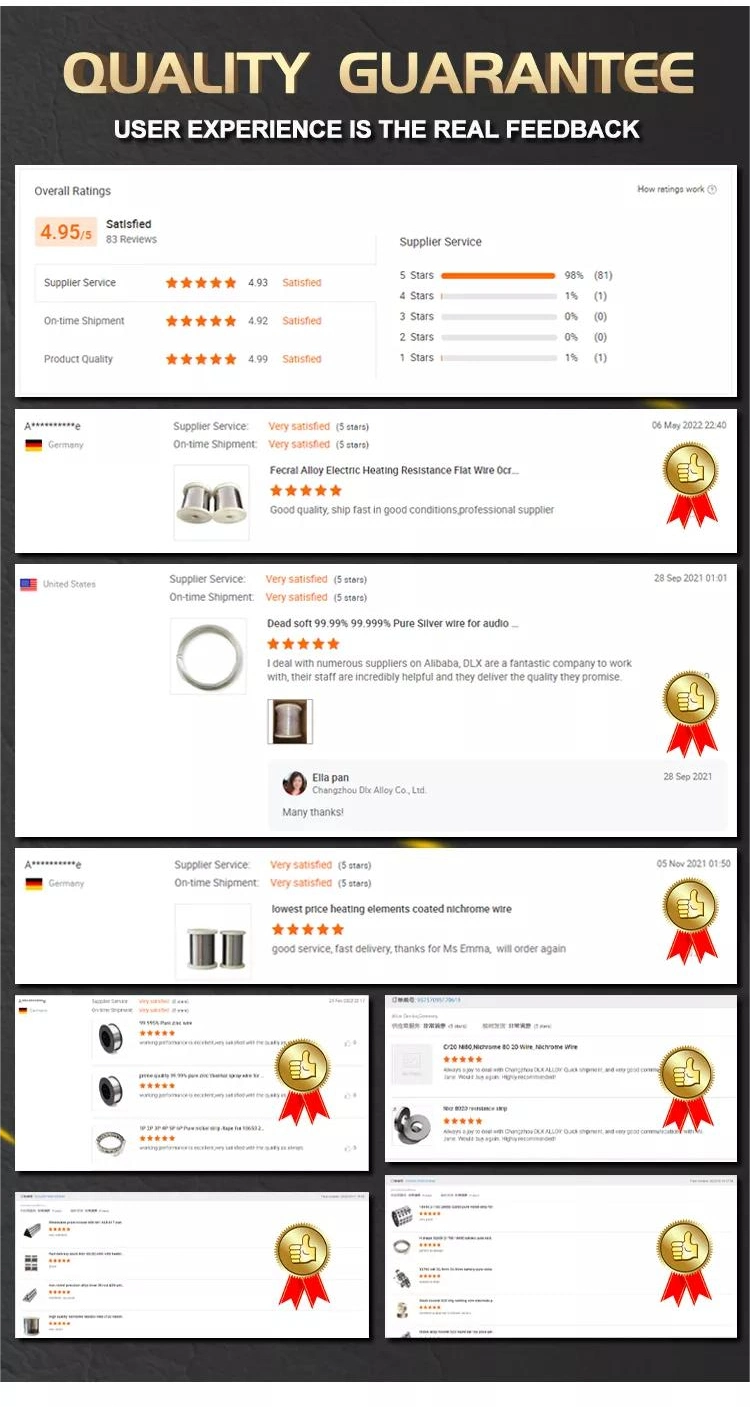

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate 1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy. Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.| Model: | C | Fe | Ni | Cr | Al+Ti | Ti | Al | Si |

| 800 | ≤0.1 | >39.5 | 30-35 | 19-23 | 0.3-1.2 | 0.15-0.6 | 0.15-0.6 | ≤1.0 |

| 800H | 0.05-0.10 | >39.5 | 30-35 | 19-23 | 0.3-1.2 | 0.15-0.6 | 0.15-0.6 | ≤1.0 |

| 800HT | 0.06-0.10 | >39.5 | 30-35 | 19-23 | 0.85-1.2 | 0.25-0.6 | 0.25-0.6 | ≤1.0 |

| 825 | ≤0.05 | Rest | 38-46 | 19.5-23.5 | -- | 0.6-1.2 | 0.2-1 | ≤0.05 |

| Products | Incoloy 825 Seamless & Welded Tube |

| Size | 5.5-110mm & Customize |

| Production Process | Cold Drawn, Cold Rolled, Bright Anneal etc |

| Application | Heating Equipment: Heating pipes, fixtures, containers, baskets and trays for sulfuric acid pickling plants, digester-liquor heaters for paper pulp. Petrochemical processing: Heat exchangers, evaporators, washing, dip tubes, etc. in phosphoric acid production. Nuclear power plants: Steam generator tubing, Flame retardant alloy for oxygen pressure applications |

| Surface | Electrolysis bright, matt, downy, mesh, belt |

| Packing | waterproof paper or wooden box |

| Available Form | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire |

Therefore, material like the Inconel 825 Cold Rolled Coiled Tube, which has been furnished under the ASTM B423 specification needs to conform to the applicable requirements such as the chemical and mechanical specified herein. Properties like the materials Tensile strength, yield strength and elongation of the Inconel 825 Seamless Tube under the specified condition and size of the Alloy 825 Welded Tubing need to also conform to the required mechanical properties. Tests such as the Hydrostatic and non-destructive electric one need to be performed on the Alloy 825 ERW Tube.