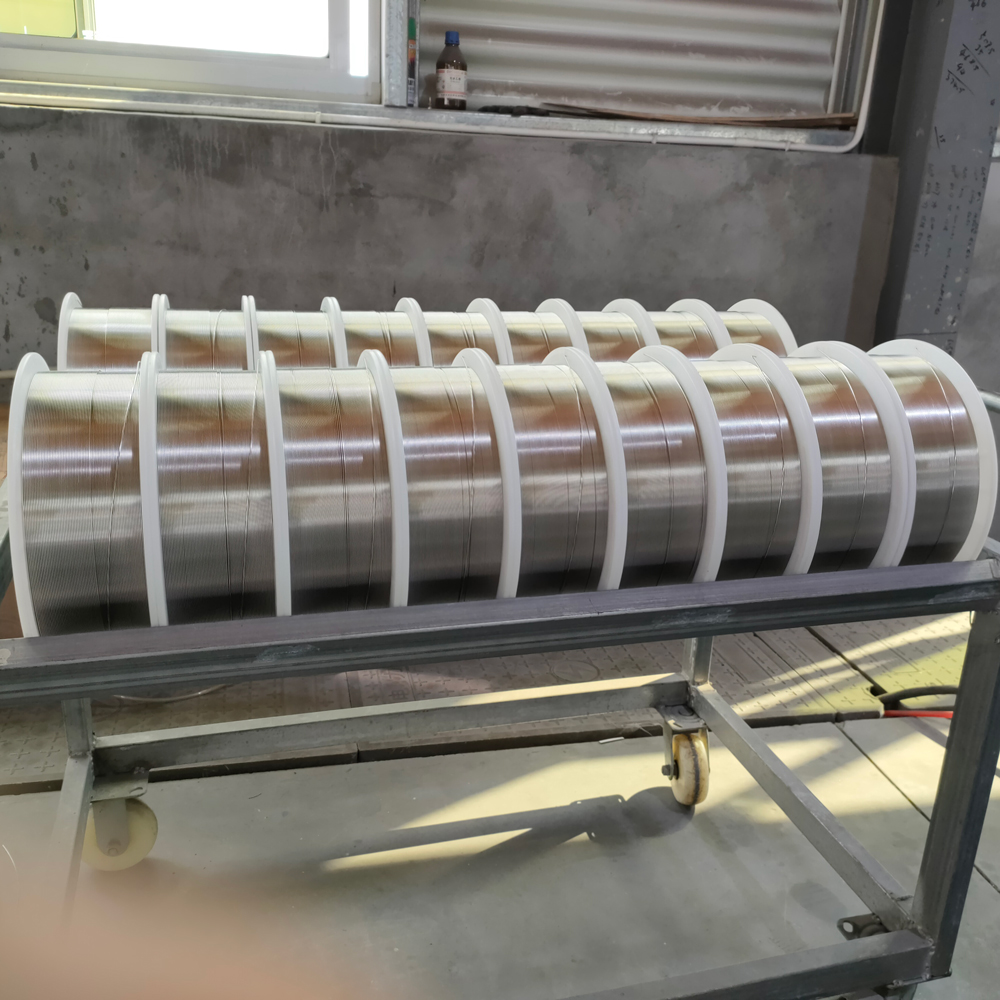

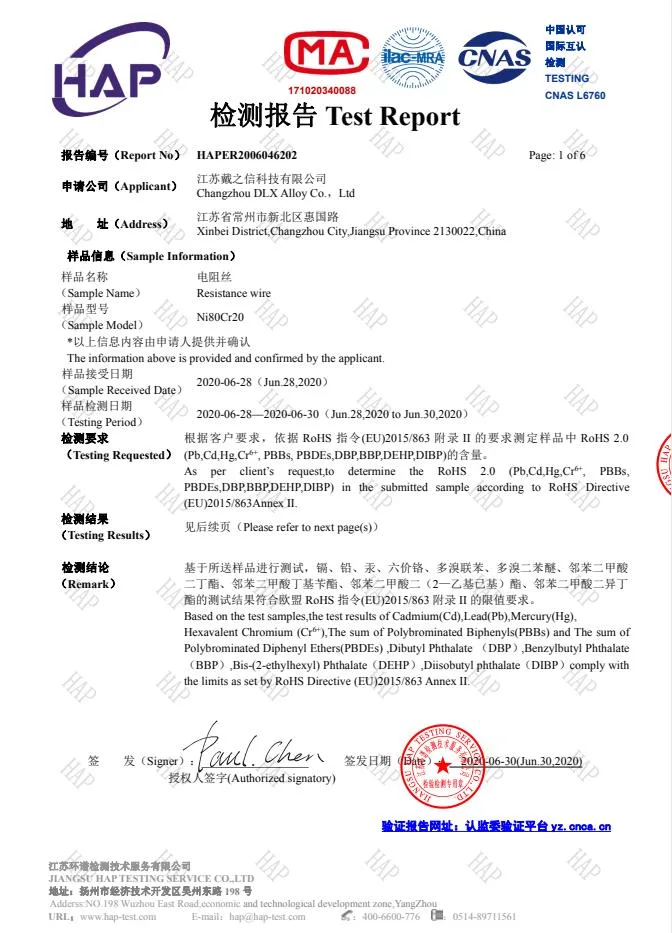

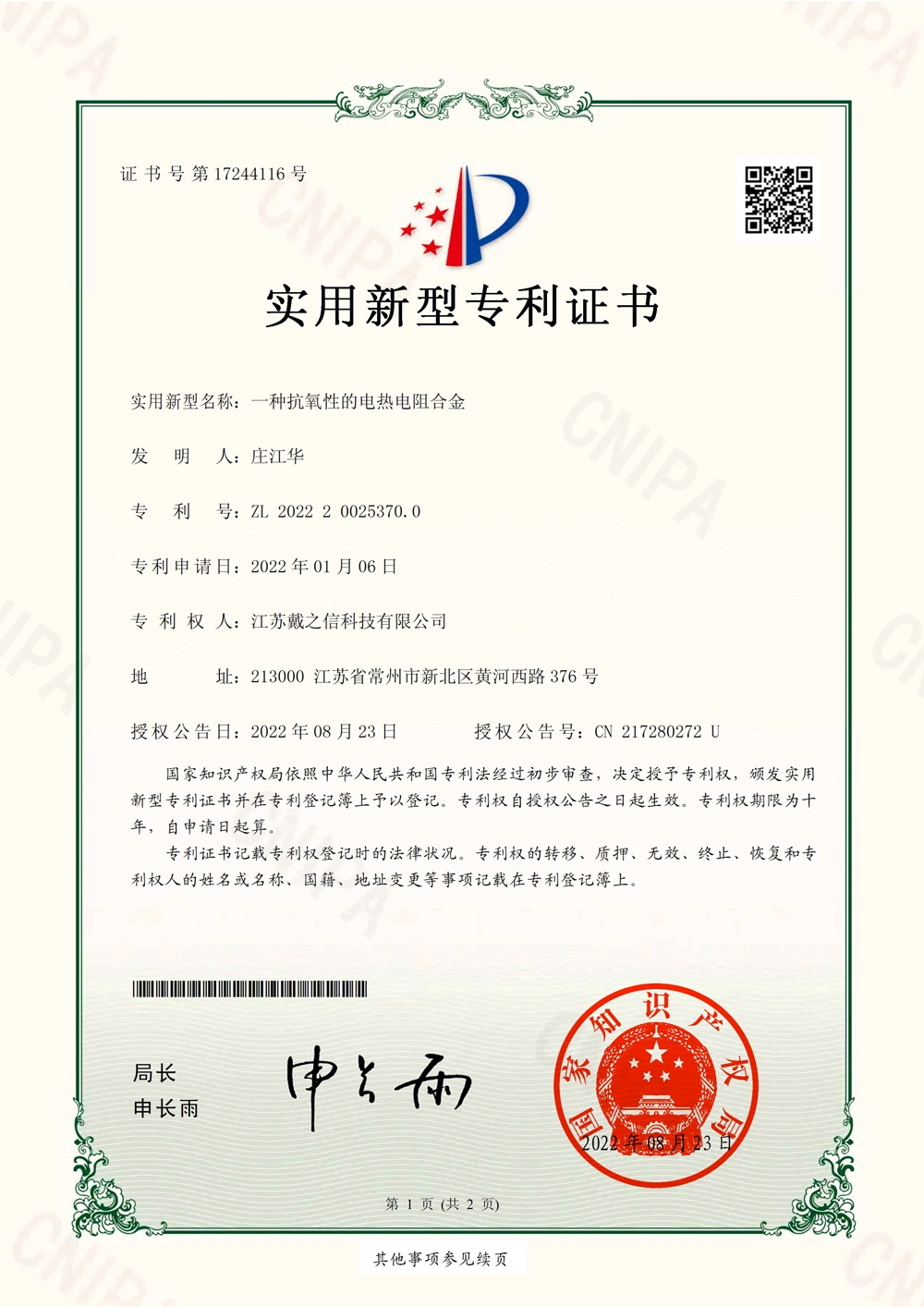

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate 1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

MONEL K-500 alloy has the same corrosion resistance as 400, but has higher mechanical strength and hardness. It has good thermal corrosion resistance and long-term organizational stability. Ni≥63, Cu27-33, Al2.3-3.15, Ti0.35-0.85, Fe≤2.0, Mn≤1.5, Si≤0.5, C≤0.25, S≤0.01 Physical Properties of K-500 Alloy Density 8.80g/cm3 Modulus of elasticity 26 000 ksi Resistivity 5.11e-005 ohm-cm Melting point 1300 - 1350 °C Magnetic 200H(At 70 F) Mechanical Properties of K-500 Alloy Tensile strength: 70-90MPa Yield strength (0.2% Offset): 482-621KSI Elongation, %: 25-60Mpa Hardness: 172-413Brinell MonelK-500 features: Monel K500 has corrosion resistance in a variety of media, resistance to chloride ion stress corrosion cracking, high strength and hardness. In the aging state, the mechanical properties of Monel 400 are about 2~3 times stronger than that of Monel 400. It still has high tensile strength at up to 650°C, good fatigue corrosion resistance, low magnetic permeability, and can reach -135 at low temperature. It is still non-magnetic at ℃. Monel K-500 application: It is mainly used to manufacture turbine blades and gas turbine blades on aero-engines whose working temperature is below 750°C; to manufacture fasteners and springs on ships; pumps and valve parts on chemical equipment; scraper blades on paper-making equipment Wait. 1. Valve seals, pump sleeves, wear rings in marine environments (high strength and seawater corrosion resistance); 2. Fasteners such as bolts are used in marine atmosphere and tidal water, and are resistant to corrosion in environments containing chloride ions; 3. Medical blades and scrapers; 4. Lanyard metal shell --- high strength, non-magnetic and seawater corrosion resistance; 5. Oil well drilling equipment such as non-magnetic drill bits, valve bodies and instrument sleeves---resistance to corrosion in chloride ion-containing media and acid gas environments; 6. Spring --- resistant to a variety of corrosive media; 7. Non-magnetic aviation instrument parts.

MONEL K-500 alloy has the same corrosion resistance as 400, but has higher mechanical strength and hardness. It has good thermal corrosion resistance and long-term organizational stability. Ni≥63, Cu27-33, Al2.3-3.15, Ti0.35-0.85, Fe≤2.0, Mn≤1.5, Si≤0.5, C≤0.25, S≤0.01 Physical Properties of K-500 Alloy Density 8.80g/cm3 Modulus of elasticity 26 000 ksi Resistivity 5.11e-005 ohm-cm Melting point 1300 - 1350 °C Magnetic 200H(At 70 F) Mechanical Properties of K-500 Alloy Tensile strength: 70-90MPa Yield strength (0.2% Offset): 482-621KSI Elongation, %: 25-60Mpa Hardness: 172-413Brinell MonelK-500 features: Monel K500 has corrosion resistance in a variety of media, resistance to chloride ion stress corrosion cracking, high strength and hardness. In the aging state, the mechanical properties of Monel 400 are about 2~3 times stronger than that of Monel 400. It still has high tensile strength at up to 650°C, good fatigue corrosion resistance, low magnetic permeability, and can reach -135 at low temperature. It is still non-magnetic at ℃. Monel K-500 application: It is mainly used to manufacture turbine blades and gas turbine blades on aero-engines whose working temperature is below 750°C; to manufacture fasteners and springs on ships; pumps and valve parts on chemical equipment; scraper blades on paper-making equipment Wait. 1. Valve seals, pump sleeves, wear rings in marine environments (high strength and seawater corrosion resistance); 2. Fasteners such as bolts are used in marine atmosphere and tidal water, and are resistant to corrosion in environments containing chloride ions; 3. Medical blades and scrapers; 4. Lanyard metal shell --- high strength, non-magnetic and seawater corrosion resistance; 5. Oil well drilling equipment such as non-magnetic drill bits, valve bodies and instrument sleeves---resistance to corrosion in chloride ion-containing media and acid gas environments; 6. Spring --- resistant to a variety of corrosive media; 7. Non-magnetic aviation instrument parts.