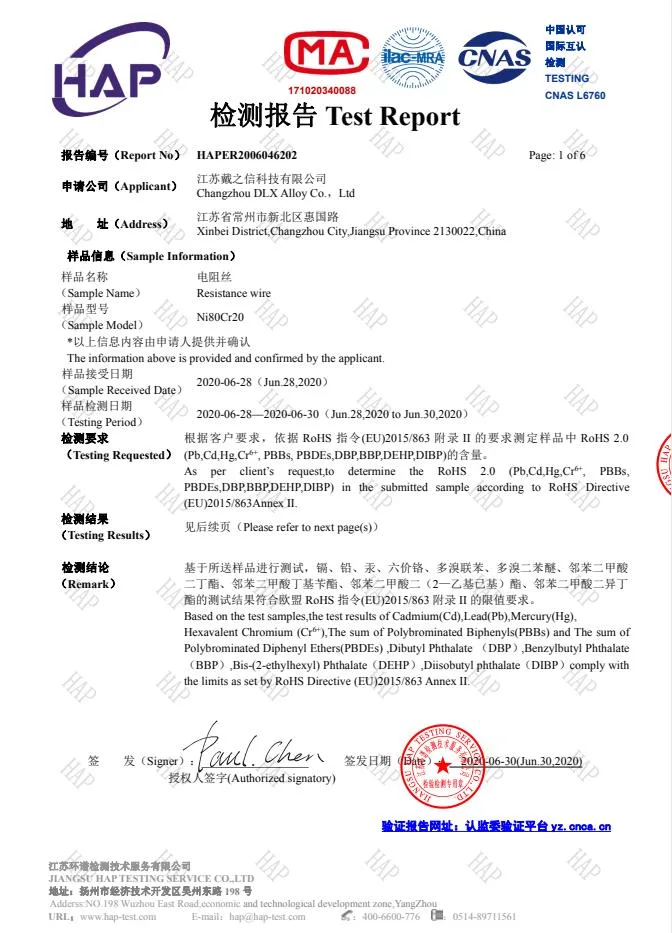

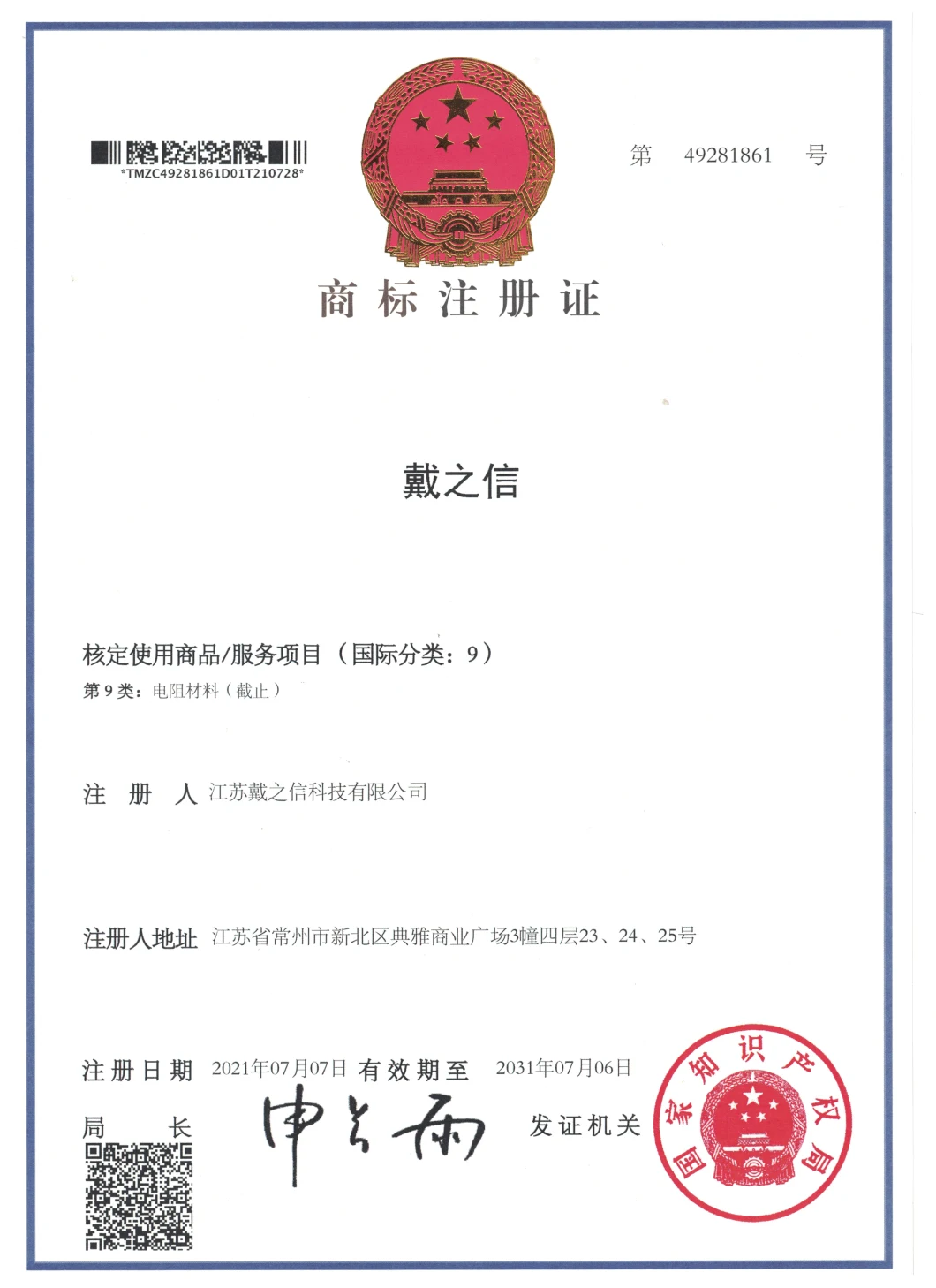

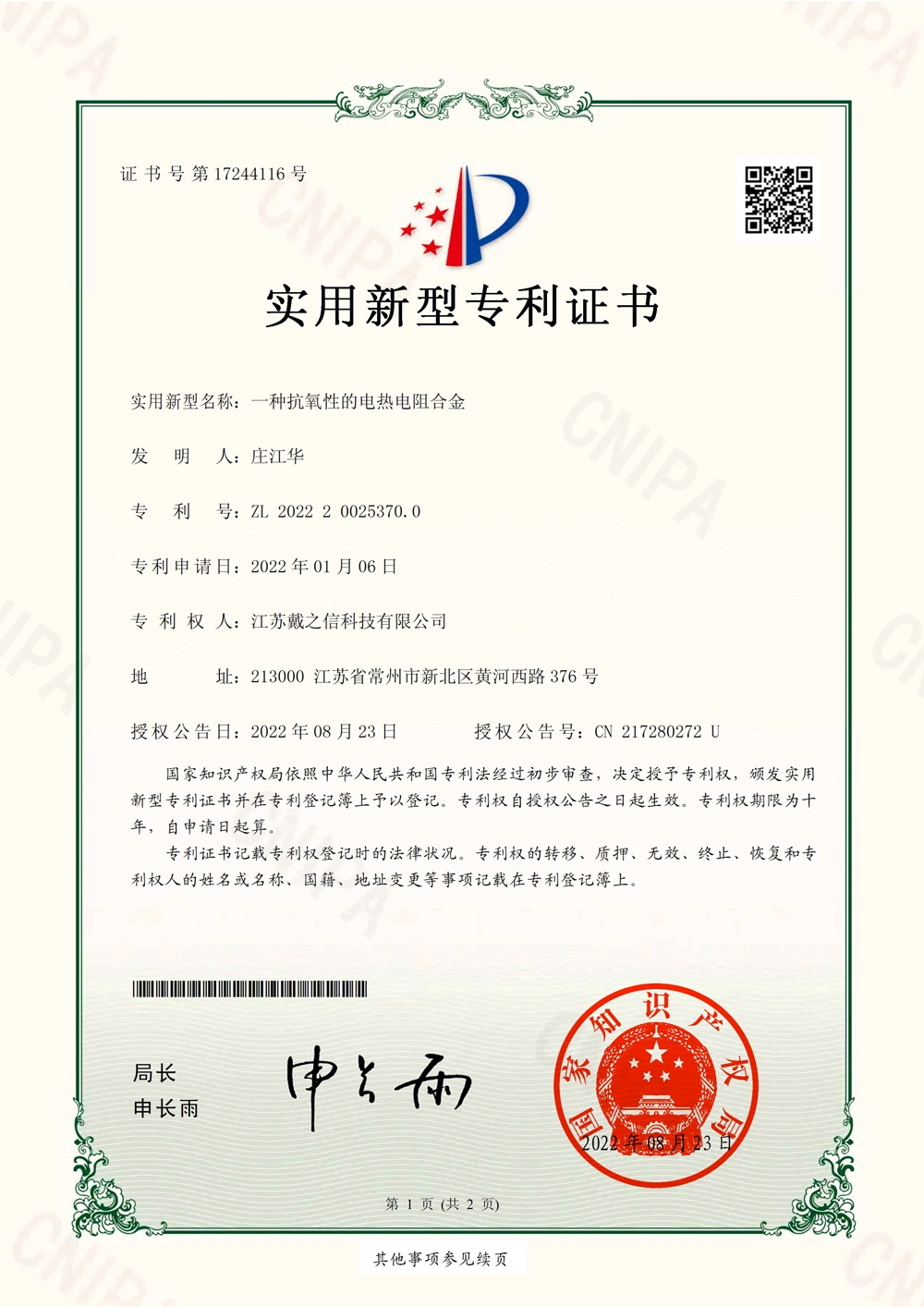

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate 1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.Thermal processing The annealing temperature should be controlled at 700-900 ℃, and rapid air cooling is recommended to obtain corrosion resistance. Time and temperature will directly affect grain size, and annealing parameters must be carefully formulated. cold working Intermediate annealing should be carried out for cold working. Has a high work hardening rate The cold forming deformation is higher than 5%, and it must be used after stress relief or annealing Monel400 welding process It can be welded by argon arc welding, plasma arc welding, gas shielded welding or manual arc welding. Pulse arc welding is the first choice, and surface treatment should be carried out after welding. Application of Monel 400: Monel400 alloy is a versatile material that can be applied in many industrial fields: Seamless water pipes, steam pipes in power plant Sea water exchangers and evaporators Sulfuric and hydrochloric acid environments crude oil distillation Pump shafts and propellers for equipment used in sea water Used by the nuclear industry to manufacture equipment for uranium refining and isotope separation Manufacture of pumps and valves for hydrochloric acid production equipment

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.Thermal processing The annealing temperature should be controlled at 700-900 ℃, and rapid air cooling is recommended to obtain corrosion resistance. Time and temperature will directly affect grain size, and annealing parameters must be carefully formulated. cold working Intermediate annealing should be carried out for cold working. Has a high work hardening rate The cold forming deformation is higher than 5%, and it must be used after stress relief or annealing Monel400 welding process It can be welded by argon arc welding, plasma arc welding, gas shielded welding or manual arc welding. Pulse arc welding is the first choice, and surface treatment should be carried out after welding. Application of Monel 400: Monel400 alloy is a versatile material that can be applied in many industrial fields: Seamless water pipes, steam pipes in power plant Sea water exchangers and evaporators Sulfuric and hydrochloric acid environments crude oil distillation Pump shafts and propellers for equipment used in sea water Used by the nuclear industry to manufacture equipment for uranium refining and isotope separation Manufacture of pumps and valves for hydrochloric acid production equipment

Monel 400 has great mechanical properties at subzero temperatures, can be used in temperatures up to 1000° F, and its melting point is 2370-2460° F. However, alloy 400 is low in strength in the annealed condition so, a variety of tempers may be used to increase the strength. Ni: balance; Cu:28-34; Si:<0.5; Mn:<2.0; C: <0.30; Fe: <2.0 Mechanical Properties of 400 Alloy Tensile strength: 480Rm N/mm2 Yield strength: 170RP0.2N/mm2 Elongation, %: 35Mpa Hardness: ≥331HB supply Bars, bars, strips, pipes, valve seats, balls, flanges and forgings are available upon negotiation. Widely used in chemical and petroleum offshore industry

Monel 400 has great mechanical properties at subzero temperatures, can be used in temperatures up to 1000° F, and its melting point is 2370-2460° F. However, alloy 400 is low in strength in the annealed condition so, a variety of tempers may be used to increase the strength. Ni: balance; Cu:28-34; Si:<0.5; Mn:<2.0; C: <0.30; Fe: <2.0 Mechanical Properties of 400 Alloy Tensile strength: 480Rm N/mm2 Yield strength: 170RP0.2N/mm2 Elongation, %: 35Mpa Hardness: ≥331HB supply Bars, bars, strips, pipes, valve seats, balls, flanges and forgings are available upon negotiation. Widely used in chemical and petroleum offshore industry | Item | Ni | Cu | Fe | Mn | C | Si | S | ||||||

| Monel 400 | ≥63 | 28-34 | ≤2.5 | ≤2 | ≤0.3 | ≤0.5 | ≤0.025 | ||||||

| Item | Density | Melting point | Tensile Strength | Yield Strength | Elongation | HB | |||||||

| Monel 400 | 8.83 g/cm3 | 1300-1390℃ | 480 | 170 | 35% | ≥331 | |||||||

| Monel 400 | Bar/Rod | Forging | Pipe | Sheet/Strip | Welding Wire | ||||||||

| Standard | ASTM B164 | ASTM B564 | ASTM B165 | ASTM B127 | ErNiCu-7 | ||||||||