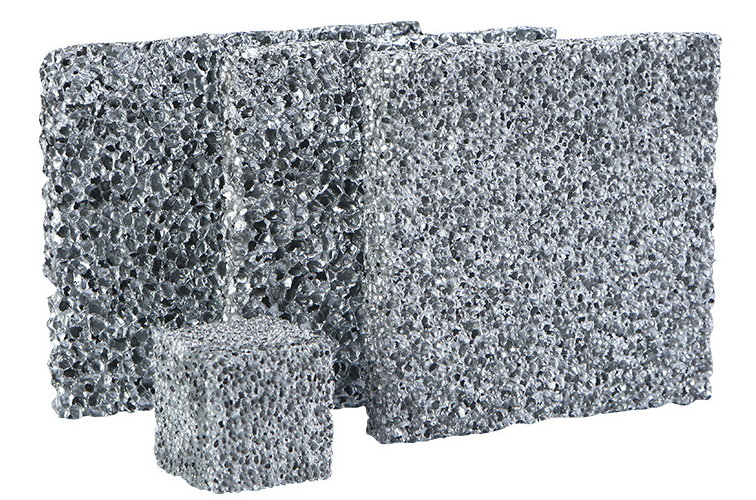

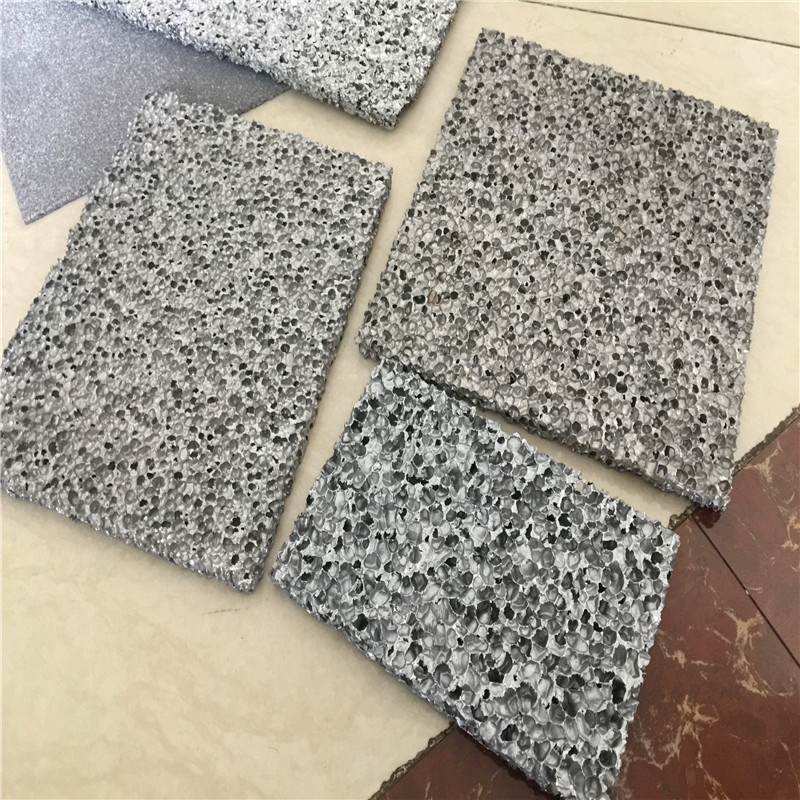

Looking closer, it is easy to find that aluminum foam is the characteristic of metal + bubbles, which is very obvious. Therefore, it also has the advantages of very superior metal materials, and because of the air bubbles, it will have the characteristics of ultra-light, sound absorption, heat resistance, and electromagnetic wave shielding.

Looking closer, it is easy to find that aluminum foam is the characteristic of metal + bubbles, which is very obvious. Therefore, it also has the advantages of very superior metal materials, and because of the air bubbles, it will have the characteristics of ultra-light, sound absorption, heat resistance, and electromagnetic wave shielding.

Anna Yang Export Manager sales9@dzxtech.cn +86 13270911653 Changzhou DZX/DLX Alloy. Co., Ltd www.dlx-alloy.com Dianyahuayuan, Huiguo Road, Xinbei District, Changzhou, Jiangsu, China

Anna Yang Export Manager sales9@dzxtech.cn +86 13270911653 Changzhou DZX/DLX Alloy. Co., Ltd www.dlx-alloy.com Dianyahuayuan, Huiguo Road, Xinbei District, Changzhou, Jiangsu, China