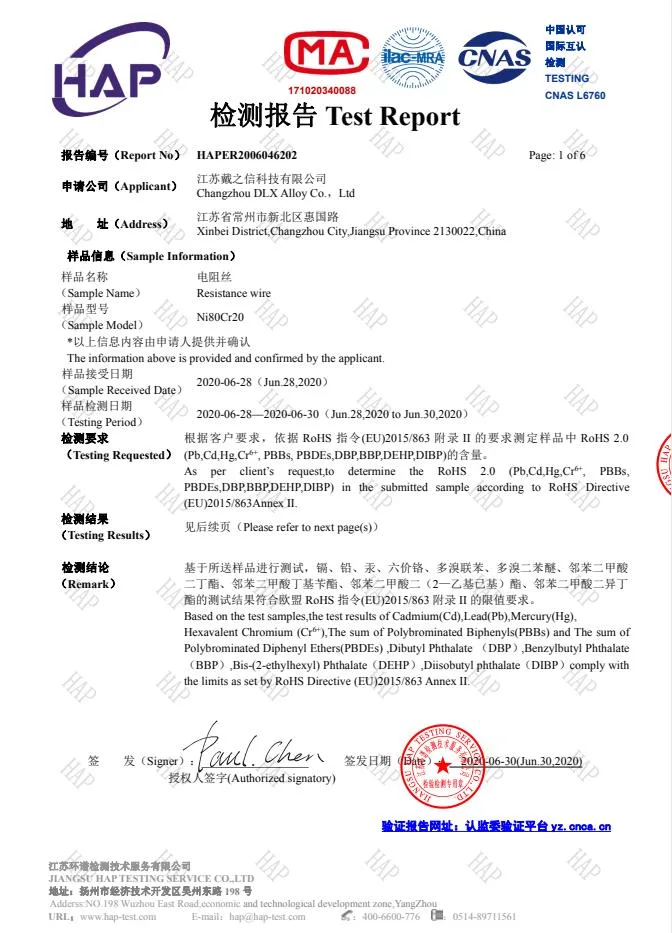

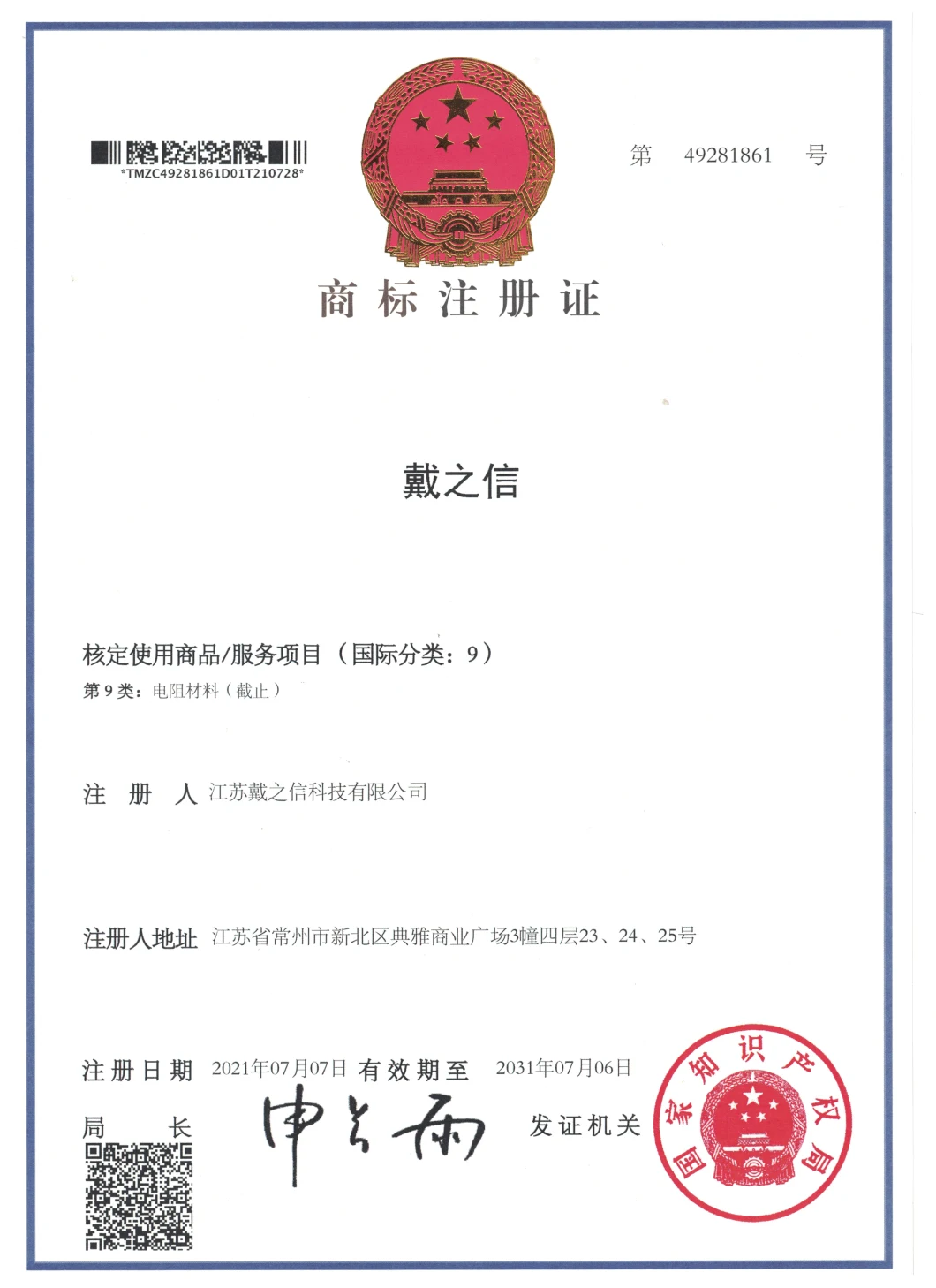

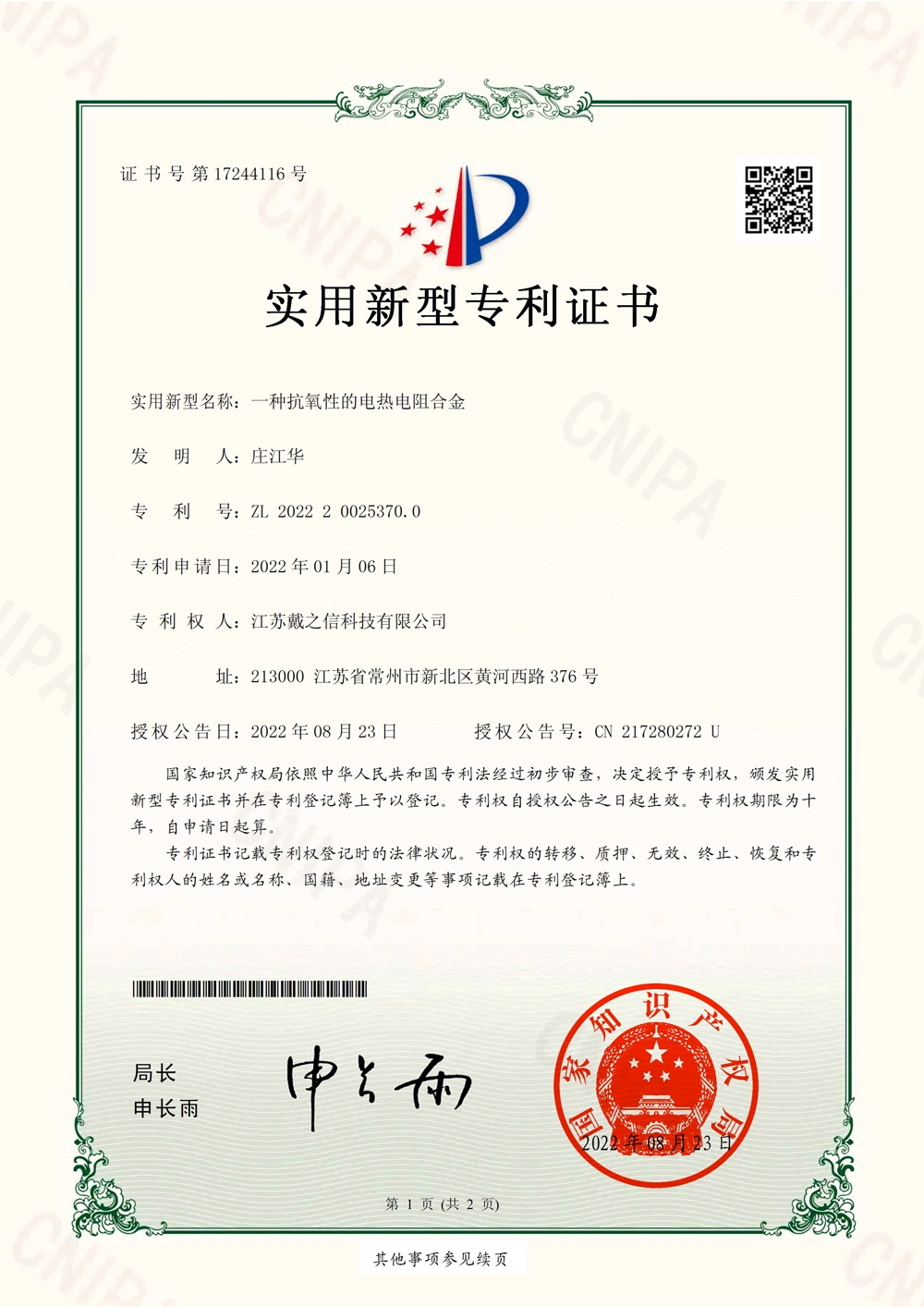

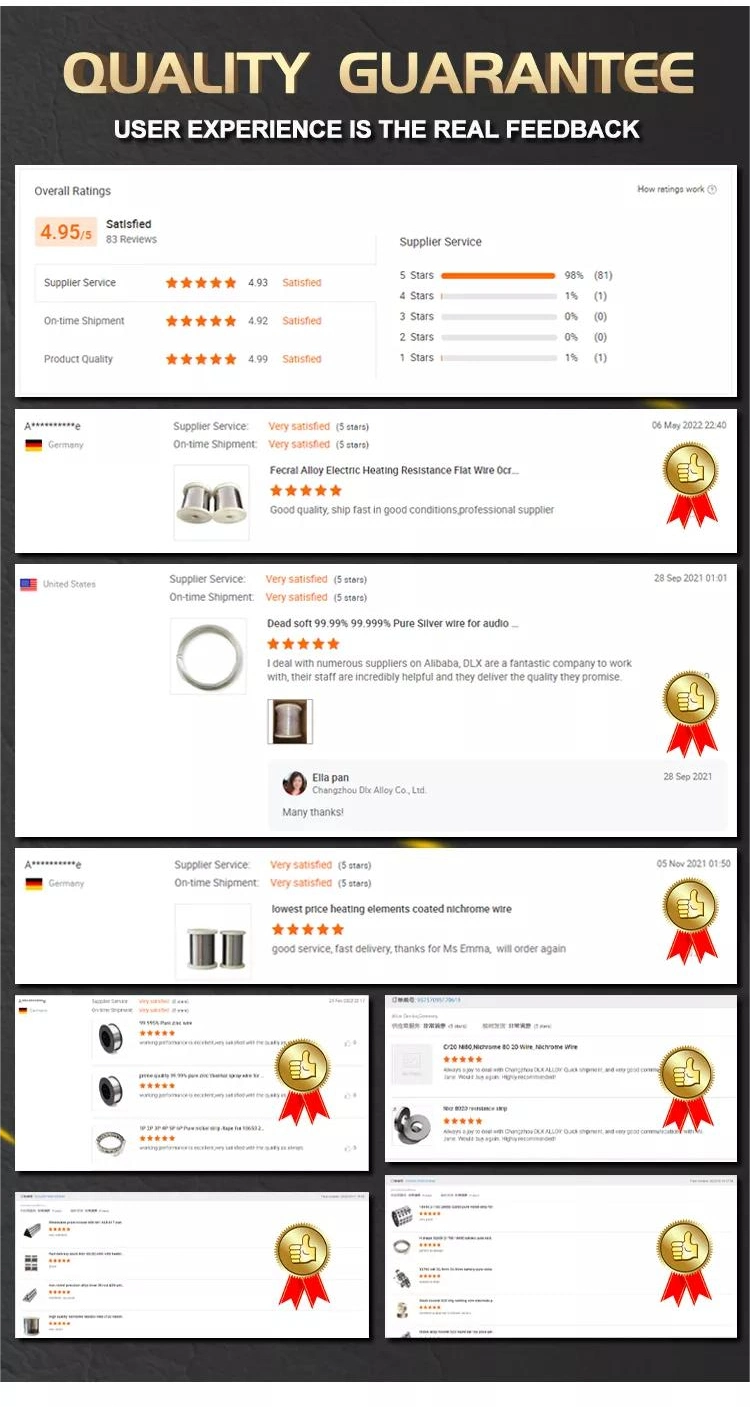

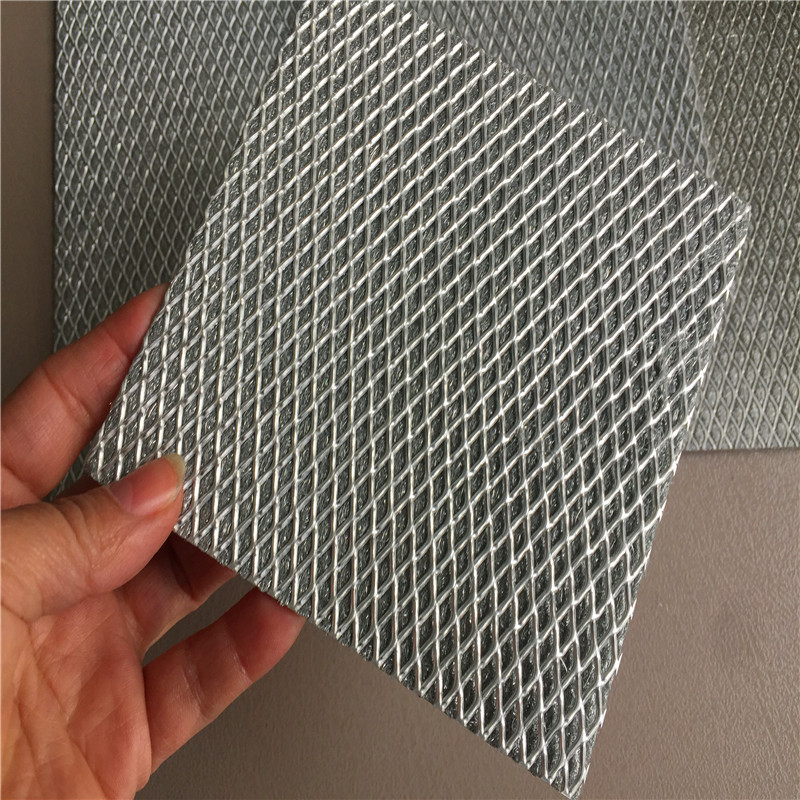

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate 1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy. Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

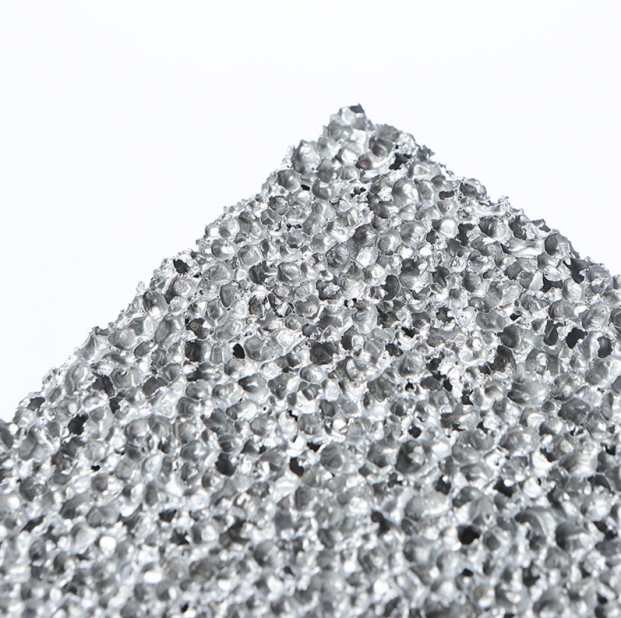

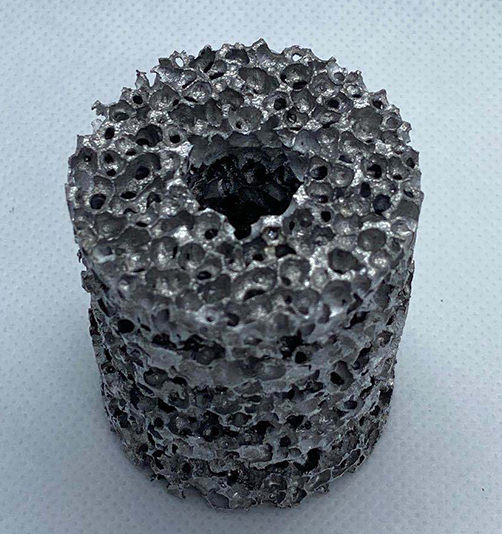

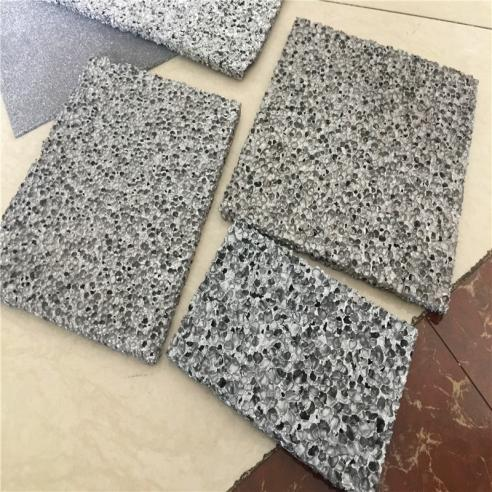

Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.| Aperture | 0.3mm-7mm(can customized) |

| Porosity | 63%-90% |

| The MAX Sound Absorption Coefficient | ≥0.8 |

| Bulk density | 0.27-1.08 g/cm3 |

| size | Customized |

| Ultra-light/low Weight | Pore diameter | Main 5 – 10 mm |

| Density | 0.25g/cm 3 – 0.85g/cm 3 | |

| Porosity | 68% ~91% | |

| Thickness | 6 -300 mm | |

| Size availability | 500*500mm, 600*600mm, 1000*500mm, 1200*600mm. Biggest size is 2400*800mm | |

| Shape | mainly, panel; customize special shape acceptable | |

| Weather Resistance | Corrosion resistance | Excellent |

| Moisture absorption | 0.00% | |

| Heat / non combustion property | A1 grade | |

| Thermal conductivity | 0.25 ~ 0.62W/M.K | |

| thermal expansivity | 19.34*10 -6/ °C | |

| Green Environmental Protection | Non toxicity,100% recyclable,Easy to process and installation | |

| Excellent Hiding Property | After surface spray absorbing material treatment | |

| Excellent Acoustic Performance | Sound insulation (20mm Thickness) | 20 ~40 db |

| Sound absorption (1000Hz -2000Hz) | 40% ~ 80% | |

| Electromagnetic Shielding | Excenllent | |

| Density | Compressive | Bending | Energy |

| (g/cm3) | Strength | Strength | Absorption |

| (Mpa) | (Mpa) | (KJ/M3) | |

| 0.25~0.30 | 3.0~4.0 | 3.0~5.0 | 1000~2000 |

| 0.30~0.40 | 4.0~7.0 | 5.0~9.0 | 2000~3000 |

| 0.40~0.50 | 7.0~11.5 | 9.0~13.5 | 3000~5000 |

| 0.50~0.60 | 11.5~15.0 | 13.5~18.5 | 5000~7000 |

| 0.60~0.70 | 15.0~19.0 | 18.5~22.0 | 7000~9000 |

| 0.70~0.80 | 19.0~21.5 | 22.0~25.0 | 9000~12000 |

| 0.80~0.85 | 21.5~32.0 | 25.0~36.0 | 12000~15000 |

Sound-absorbing and sound-insulating materials: Aluminum foam can be used for urban light rail, elevated highways, underground tunnels, noise control of mechanical equipment, and improvement of acoustic rooms, multi-functional halls and other indoor sound effects. Sound-absorbing foamed aluminum is pasted on concrete or steel structures, and erected on both sides of viaducts and light rails as large sound-absorbing walls, which can reduce urban traffic noise. Sound-insulating aluminum foam can be used for noise isolation in factory computer rooms, machinery and equipment, and outdoor construction sites, solving many limitations of widely used sound-absorbing materials such as glass wool and asbestos 1. Rail transit industry. Such as heat insulation and sound insulation, energy absorption and fire prevention, and anti-virus components in carriages and containers. 2. Environmental protection fields in urban construction, such as: soundproof screens; 3. Automobile manufacturing. Such as: bumpers and mufflers. 4. Energy-saving buildings. Such as: thermal insulation walls and fire insulation doors, energy-saving mobile houses. 5. Military industry, sound-absorbing and anti-magnetic components, such as: sandwich panels for tanks and submarine shells. 6. The heat and sound insulation, shockproof and energy absorbing elements of other machinery manufacturing, aviation industry and other products can be made of foamed aluminum materials.

Sound-absorbing and sound-insulating materials: Aluminum foam can be used for urban light rail, elevated highways, underground tunnels, noise control of mechanical equipment, and improvement of acoustic rooms, multi-functional halls and other indoor sound effects. Sound-absorbing foamed aluminum is pasted on concrete or steel structures, and erected on both sides of viaducts and light rails as large sound-absorbing walls, which can reduce urban traffic noise. Sound-insulating aluminum foam can be used for noise isolation in factory computer rooms, machinery and equipment, and outdoor construction sites, solving many limitations of widely used sound-absorbing materials such as glass wool and asbestos 1. Rail transit industry. Such as heat insulation and sound insulation, energy absorption and fire prevention, and anti-virus components in carriages and containers. 2. Environmental protection fields in urban construction, such as: soundproof screens; 3. Automobile manufacturing. Such as: bumpers and mufflers. 4. Energy-saving buildings. Such as: thermal insulation walls and fire insulation doors, energy-saving mobile houses. 5. Military industry, sound-absorbing and anti-magnetic components, such as: sandwich panels for tanks and submarine shells. 6. The heat and sound insulation, shockproof and energy absorbing elements of other machinery manufacturing, aviation industry and other products can be made of foamed aluminum materials.