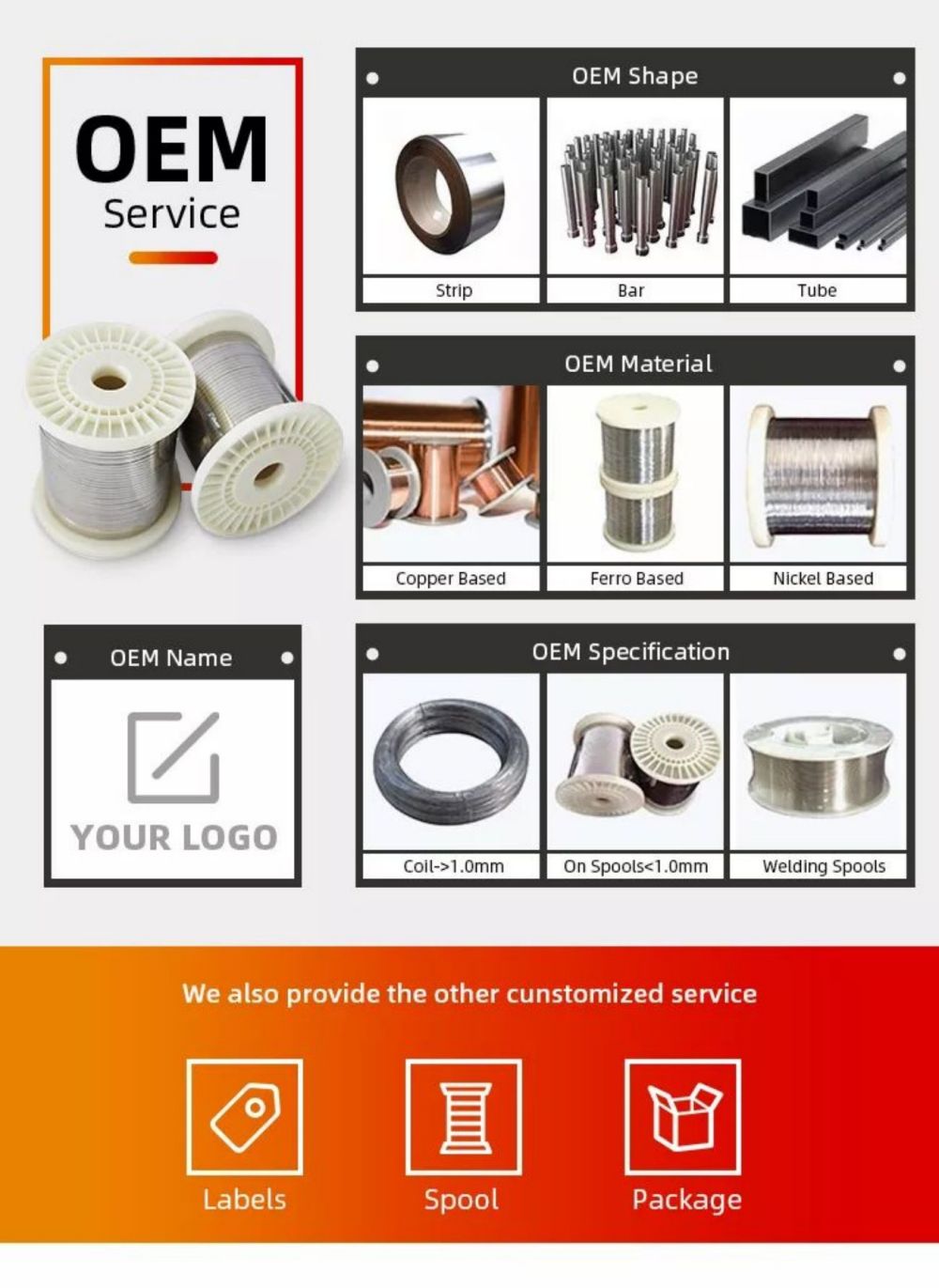

OEM service Low MOQ Sample available Customize label and package Fast delivery&Constant good qualityCould you help to design the product? Yes, we have excellent R&D team, OEM/ODM orders Do you provide free samples? Yes, we can provide a free sample for testing,buyer should bear all the shipping costs. What is your payment terms? T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal What is the lead time? Usually sample lead time is 7 days after payment has been confirmed.We can supply type of : wire, ribbon,strip, bar, sheet 1.Cold rolled strips: 0.03~0.l0×180~250mm >0.10~1.00×10~250mm >1.00~2.50×100~250mm 2. Cold drown wires: 0.l0~6.00mm 3. Hot rolled flat products: 4.50~20.0×50~250mm 4. Hot forged bars: Φ20.0~100.0mm / bar

OEM service Low MOQ Sample available Customize label and package Fast delivery&Constant good qualityCould you help to design the product? Yes, we have excellent R&D team, OEM/ODM orders Do you provide free samples? Yes, we can provide a free sample for testing,buyer should bear all the shipping costs. What is your payment terms? T/T,L/C,D/A,D/P,Western Union,MoneyGram,Paypal What is the lead time? Usually sample lead time is 7 days after payment has been confirmed.We can supply type of : wire, ribbon,strip, bar, sheet 1.Cold rolled strips: 0.03~0.l0×180~250mm >0.10~1.00×10~250mm >1.00~2.50×100~250mm 2. Cold drown wires: 0.l0~6.00mm 3. Hot rolled flat products: 4.50~20.0×50~250mm 4. Hot forged bars: Φ20.0~100.0mm / bar

| ASTM | UNS | Werkstoff |

|

|

|

| F15 | K94610 | 1.3981 | FeNi29Co17

| 4J29 | Alloy K |

| Nickel | Ni | 28.5-29.5 |

| Iron | Fe | Balance |

| Carbon | C | 0.03 max |

| Silicon | Si | 0.3 max |

| Manganese | Mn | 0.50max |

| Sulphur | S | 0.02 max |

| Phosphorus | P | 0.02 max |

| Chromium | Cr | 0.2 max |

| Cobalt | Co | 16.8-17.8 |

| Copper | Cu | 0.2 max |

| Molybdenum | Mo | 0.2 max |

Physical Properties

| Density (g/cm3) | Resistivity at 20℃(Ωmm2/m) | Temperature Coefficient of Resistance (20℃~100℃)X10-5/℃ | Curie point (Tc/ ℃) | Elastic Modulus (E/ Gpa) |

| 8.2 | 0.48 | 3.7~3.9 | 430 | 138 |

| θ/℃ | α1/10-6℃-1 | θ/℃ | α1/10-6℃-1 |

| 20~60 | 7.8 | 20~500 | 6.2 |

| 20~100 | 6.4 | 20~550 | 7.1 |

| 20~200 | 5.9 | 20~600 | 7.8 |

| 20~300 | 5.3 | 20~700 | 9.2 |

| 20~400 | 5.1 | 20~800 | 10.2 |

| 20~450 | 5.3 | 20~900 | 11.4 |