| CHEMICAL COMPOSITION | |||||||

| Alloy | Ni+Co % | Mn % | Fe % | Si % | Cu % | C % | S % |

| Nickel 201 | Min 99.2 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.02 | Max 0.01 |

| Nickel 200 | Min | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.15 | Max 0.01 |

| 99 | |||||||

| Physical Data | |||||||

| Density | Specific Heat | Electrical Resistivity | Melting Point | Thermal Conductivity | Mean Coeff Thermal Expansion | ||

| 8.89g/cm3 | 0.109(456 J/kg.℃) | 0.096×10-6ohm.m | 1435-1446℃ | 70.2 W/m-K | 13.3×10-6m/m.℃ | ||

| Mechanical Properties | Tensile Strength | Yield Strength | Elongation | Standard | |||

| Nickel 200 | 462 Mpa | 148 Mpa | 47% | ASTM B161/B163/B725/B751 | |||

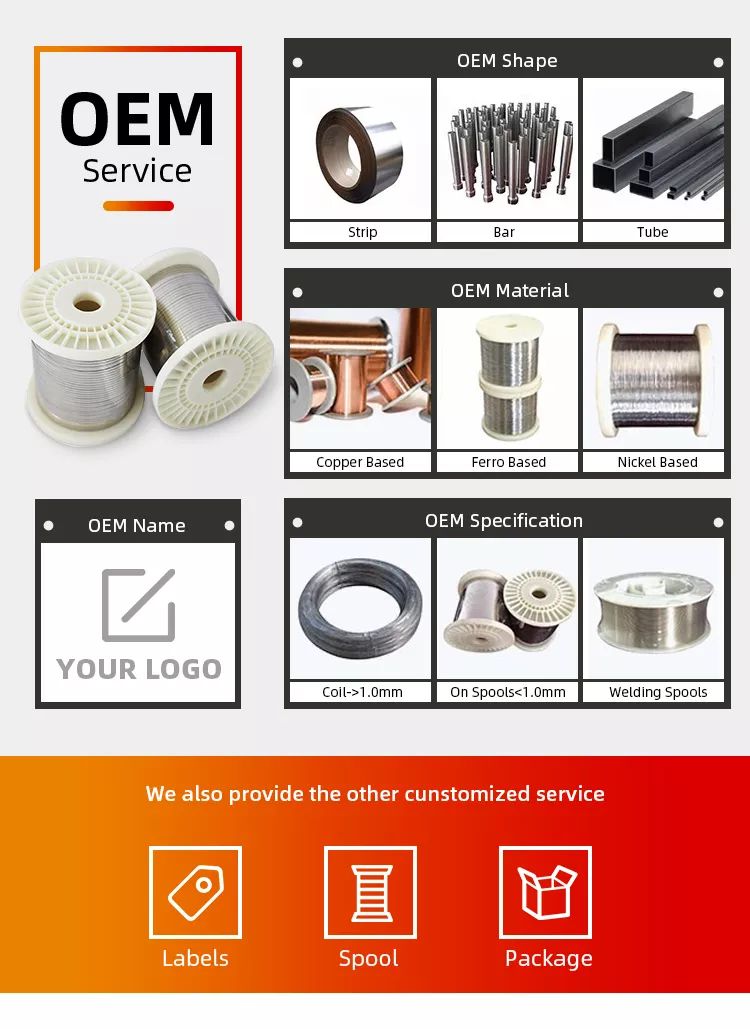

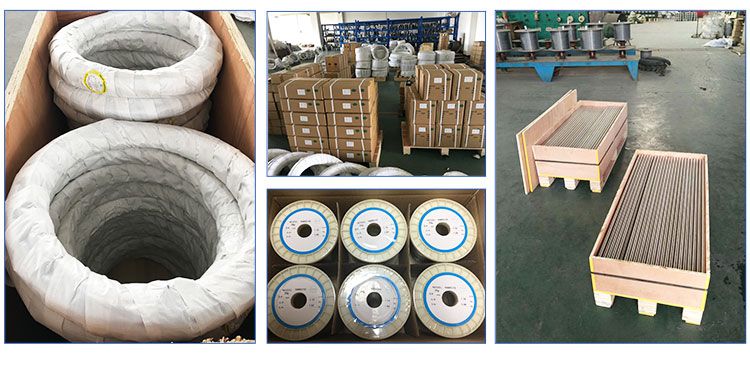

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate At present, nickel and its alloy are used in special purpose parts, instrument manufacturing, machine manufacturing, rocket technology equipment, atomic reactor, used in the production of alkaline battery, porous filter, catalyst, and parts and semi-products of anti-corrosion coating, nickel is regarded as an important strategic material in national economic construction, the effective development and comprehensive utilization of its resources has been paid attention to by all countries.

At present, nickel and its alloy are used in special purpose parts, instrument manufacturing, machine manufacturing, rocket technology equipment, atomic reactor, used in the production of alkaline battery, porous filter, catalyst, and parts and semi-products of anti-corrosion coating, nickel is regarded as an important strategic material in national economic construction, the effective development and comprehensive utilization of its resources has been paid attention to by all countries. 1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, We can provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, We can provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

* Manufacture and handling of sodium hydroxide, particularly at temperature above 300C. * Production of viscose rayon. Manufacture of soap. * Analine hydrochloride production and in the chlorination of aliphatic hydrocarbons such as benzene, methane and ethane. * Manufacture of vinyl chloride monomer. * Reactors and vessels in which fluorine is generated and reacted with hydrocarbons. * Processes using caustic alkalines * Food Processing * Synthethic Fiber Production

* Manufacture and handling of sodium hydroxide, particularly at temperature above 300C. * Production of viscose rayon. Manufacture of soap. * Analine hydrochloride production and in the chlorination of aliphatic hydrocarbons such as benzene, methane and ethane. * Manufacture of vinyl chloride monomer. * Reactors and vessels in which fluorine is generated and reacted with hydrocarbons. * Processes using caustic alkalines * Food Processing * Synthethic Fiber Production

1. With weldability, high electrical conductivity, suitable linear expansion coefficient

2. Good strength at high temperature, low resistivity

3. High melting point, corrosion resistance, good mechanical properties, in hot and cold state have good pressure workability, easy to degassing, suitable for radio, electric light source, mechanical manufacturing, chemical industry, is an important structural material in vacuum electronic devices.

| Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

| N4 | 99.8 | 0.015 | 0.03 | 0.002 | 0.01 | 0.01 | 0.001 | 0.001 | 0.04 |

| N6 | 99.6 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

| Ni201 | ≥99.0 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

| Ni200 | ≥99.2 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Physical Data | |

| Density | 8.89g/cm3 |

| Specific Heat | 0.109(456 J/kg.ºC) |

| Electrical Resistivity | 0.096×10-6ohm.m |

| Melting Point | 1435-1446ºC |

| Thermal Conductivity | 70.2 W/m-K |

| Mean Coeff Thermal Expansion | 13.3×10-6m/m.ºC |

| Typical Mechanical Properties | |

| Mechanical Properties | Nickel 200 |

| Tensile Strength | 462 Mpa |

| Yield Strength | 148 Mpa |

| Elongation | 47% |

| Our Production Standard | |||||

|

| Bar | Forging | Pipe | Sheet/Strip | Wire |

| ASTM | ASTM B160 | ASTM B564 | ASTM B161/B163/B725/B751 | AMS B162 | ASTM B166 |