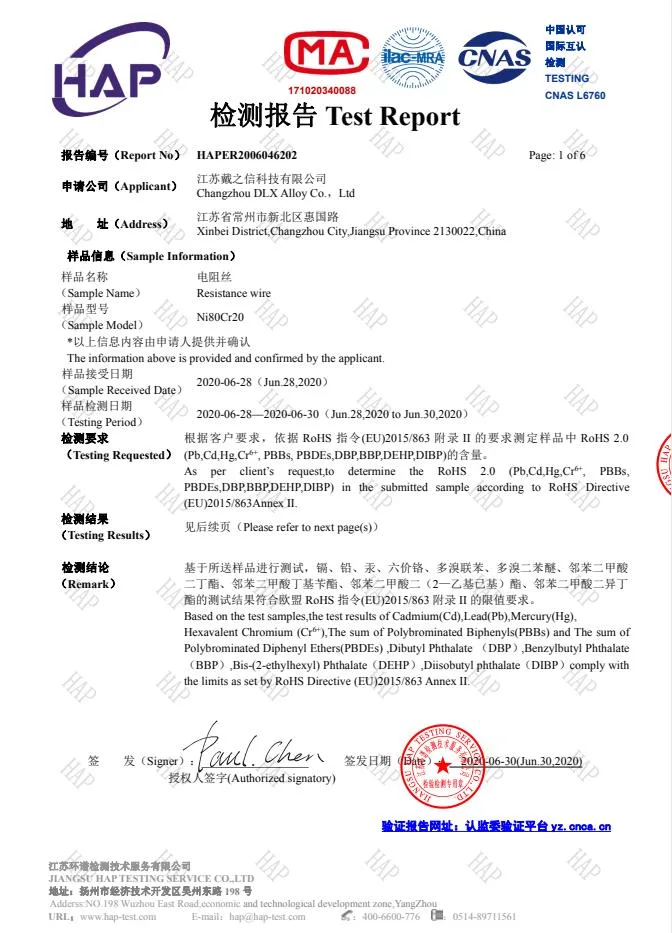

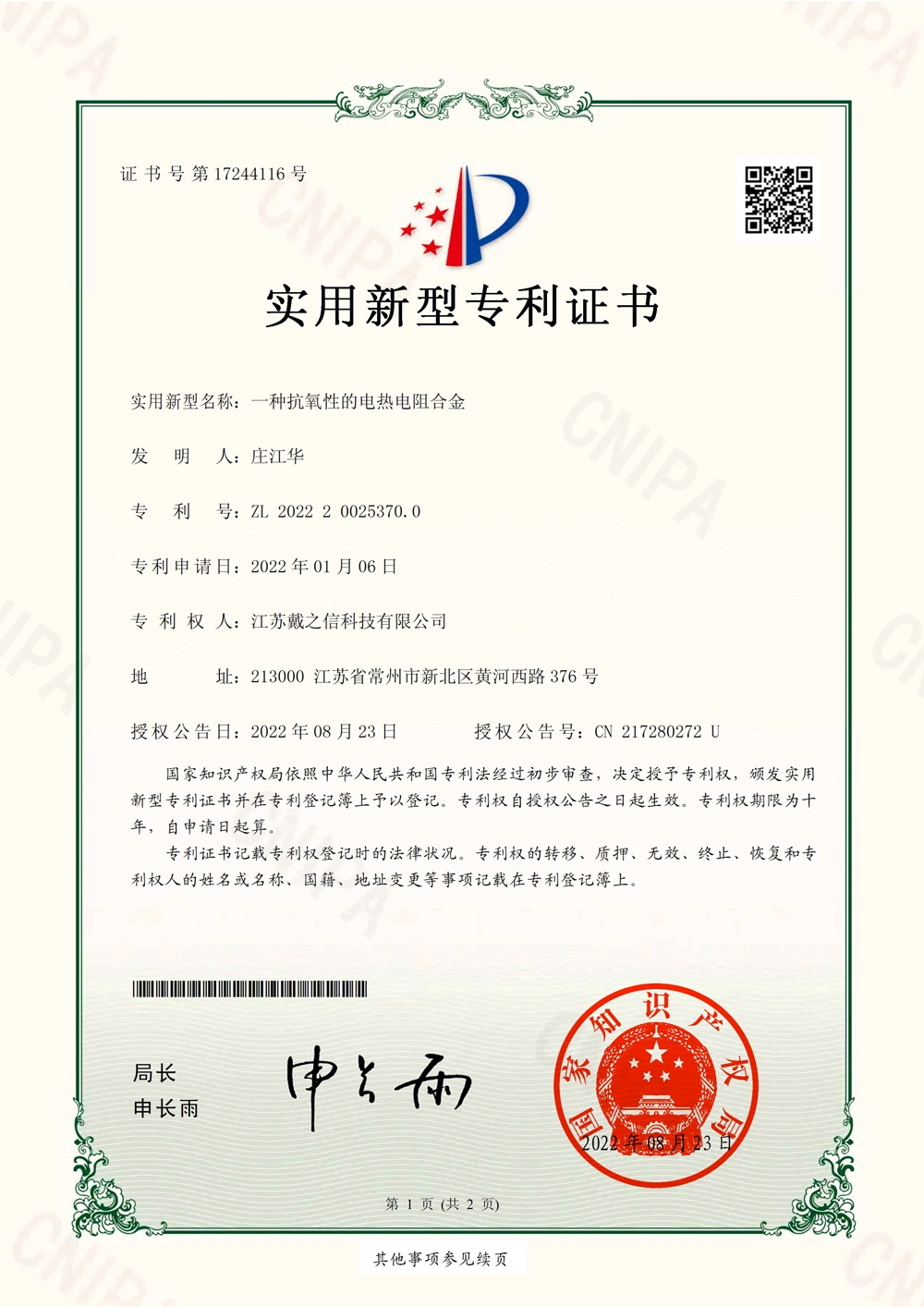

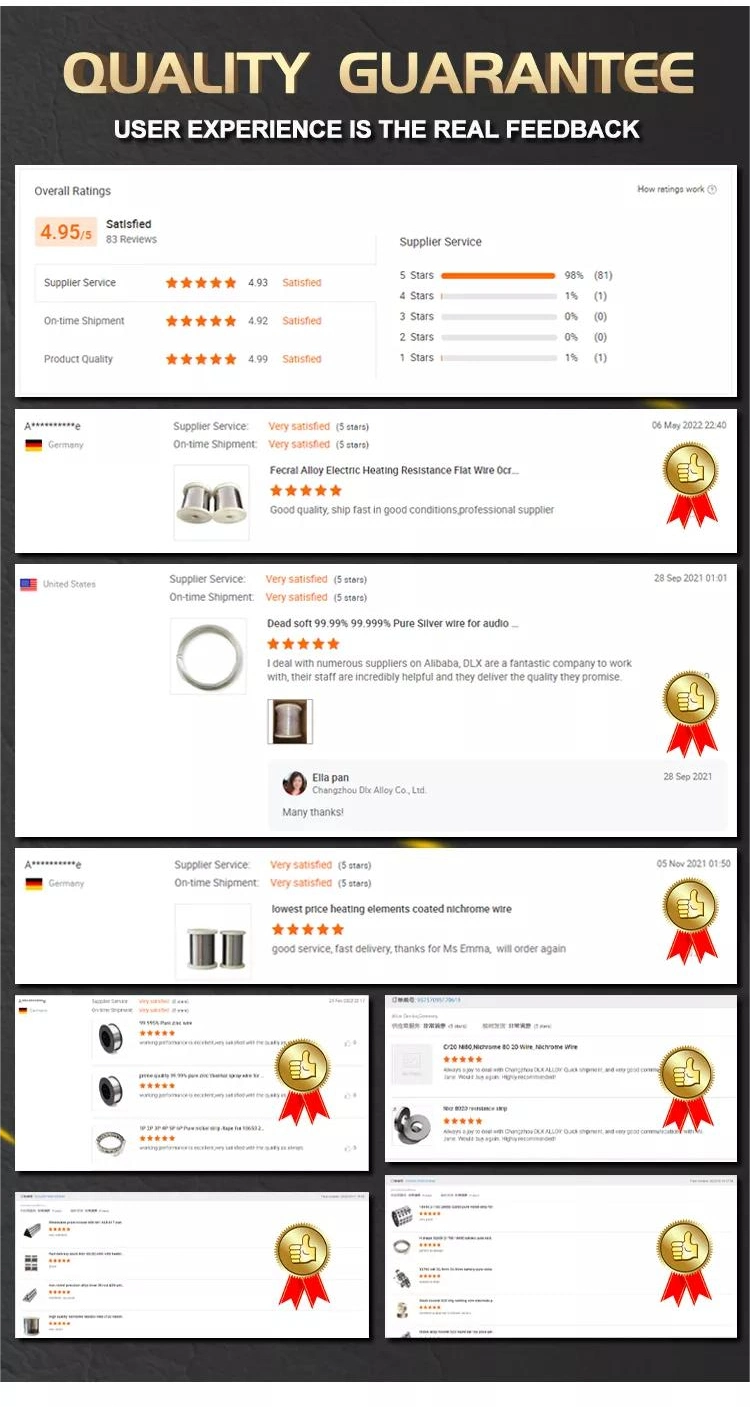

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate 1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy. Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.| Model: | C | Fe | Ni | Cr | Al+Ti | Ti | Al | Si |

| 800 | ≤0.1 | >39.5 | 30-35 | 19-23 | 0.3-1.2 | 0.15-0.6 | 0.15-0.6 | ≤1.0 |

| 800H | 0.05-0.10 | >39.5 | 30-35 | 19-23 | 0.3-1.2 | 0.15-0.6 | 0.15-0.6 | ≤1.0 |

| 800HT | 0.06-0.10 | >39.5 | 30-35 | 19-23 | 0.85-1.2 | 0.25-0.6 | 0.25-0.6 | ≤1.0 |

| 825 | ≤0.05 | Rest | 38-46 | 19.5-23.5 | -- | 0.6-1.2 | 0.2-1 | ≤0.05 |

| Density | Melting Point | Coefficient of Expansion | Modulus of Rigidity | Modulus of Elasticity |

| 8.14g/cm3 | 1400°C | 14.0μm/m °C (20 – 100 °C) | 71.8 KN/mm² | 189 KN/mm² |

| 0.294 lb/in³ | 2550 °F | 7.8 x 10-6 in/in °F (70 – 212 °F) | 11009 ksi | 28428 ksi |

| Products | Incoloy Wire 800 Nickel Alloy for heater |

| Size | 0.5-7.5mm |

| Production Process | Cold Drawn, Cold Rolled, Bright Anneal etc |

| Application | Heating Equipment: Heating pipes, fixtures, containers, baskets and trays for sulfuric acid pickling plants, digester-liquor heaters for paper pulp. Petrochemical processing: Heat exchangers, evaporators, washing, dip tubes, etc. in phosphoric acid production. Nuclear power plants: Steam generator tubing, Flame retardant alloy for oxygen pressure applications |

| Surface | Electrolysis bright, matt, downy, mesh, belt |

| Packing | waterproof paper or wooden box |

| Available Form | Pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire |

INCOLOY alloy 800 is a widely used material for construction of equipment requiring corrosion resistance, heat resistance, strength, and stability for service up to 1500°F (816°C). Alloy 800 offers general corrosion resistance to many aqueous media and, by virtue of its content of nickel, resists stress corrosion cracking. At elevated temperatures it offers resistance to oxidation, carburization, and sulfidation along with rupture and creep strength. For applications requiring greater resistance to stress rupture and creep, especially at temperatures above 1500°F (816°C), INCOLOY alloys 800H and 800HT are used. INCOLOY alloy 800 is used in a variety of applications involving exposure to corrosive environments and high temperatures. It is used for heat-treating equipment such as baskets, trays, and fixtures. In chemical and petrochemical processing, the alloy is used for heat exchangers and other piping systems in nitric acid media especially where resistance to chloride stress-corrosion cracking is required. In nuclear power plants, it is used for steam-generator tubing. The alloy is often used in domestic appliances for sheathing of electric heating elements. In the production of paper pulp, digester-liquor heaters are often made of alloy 800. In petroleum processing, the alloy is used for heat exchangers that air cool the process stream.

INCOLOY alloy 800 is a widely used material for construction of equipment requiring corrosion resistance, heat resistance, strength, and stability for service up to 1500°F (816°C). Alloy 800 offers general corrosion resistance to many aqueous media and, by virtue of its content of nickel, resists stress corrosion cracking. At elevated temperatures it offers resistance to oxidation, carburization, and sulfidation along with rupture and creep strength. For applications requiring greater resistance to stress rupture and creep, especially at temperatures above 1500°F (816°C), INCOLOY alloys 800H and 800HT are used. INCOLOY alloy 800 is used in a variety of applications involving exposure to corrosive environments and high temperatures. It is used for heat-treating equipment such as baskets, trays, and fixtures. In chemical and petrochemical processing, the alloy is used for heat exchangers and other piping systems in nitric acid media especially where resistance to chloride stress-corrosion cracking is required. In nuclear power plants, it is used for steam-generator tubing. The alloy is often used in domestic appliances for sheathing of electric heating elements. In the production of paper pulp, digester-liquor heaters are often made of alloy 800. In petroleum processing, the alloy is used for heat exchangers that air cool the process stream.