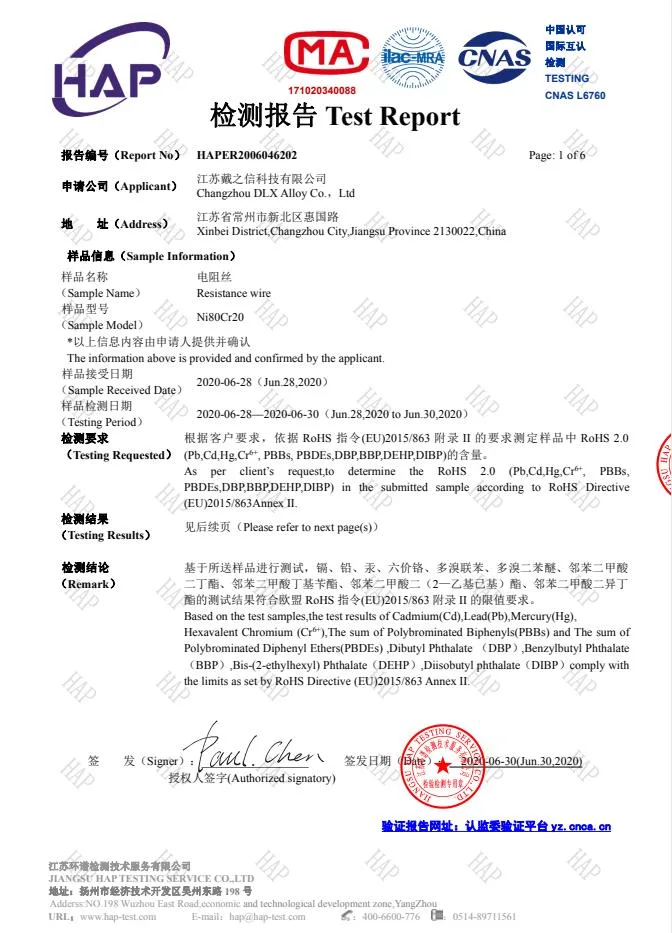

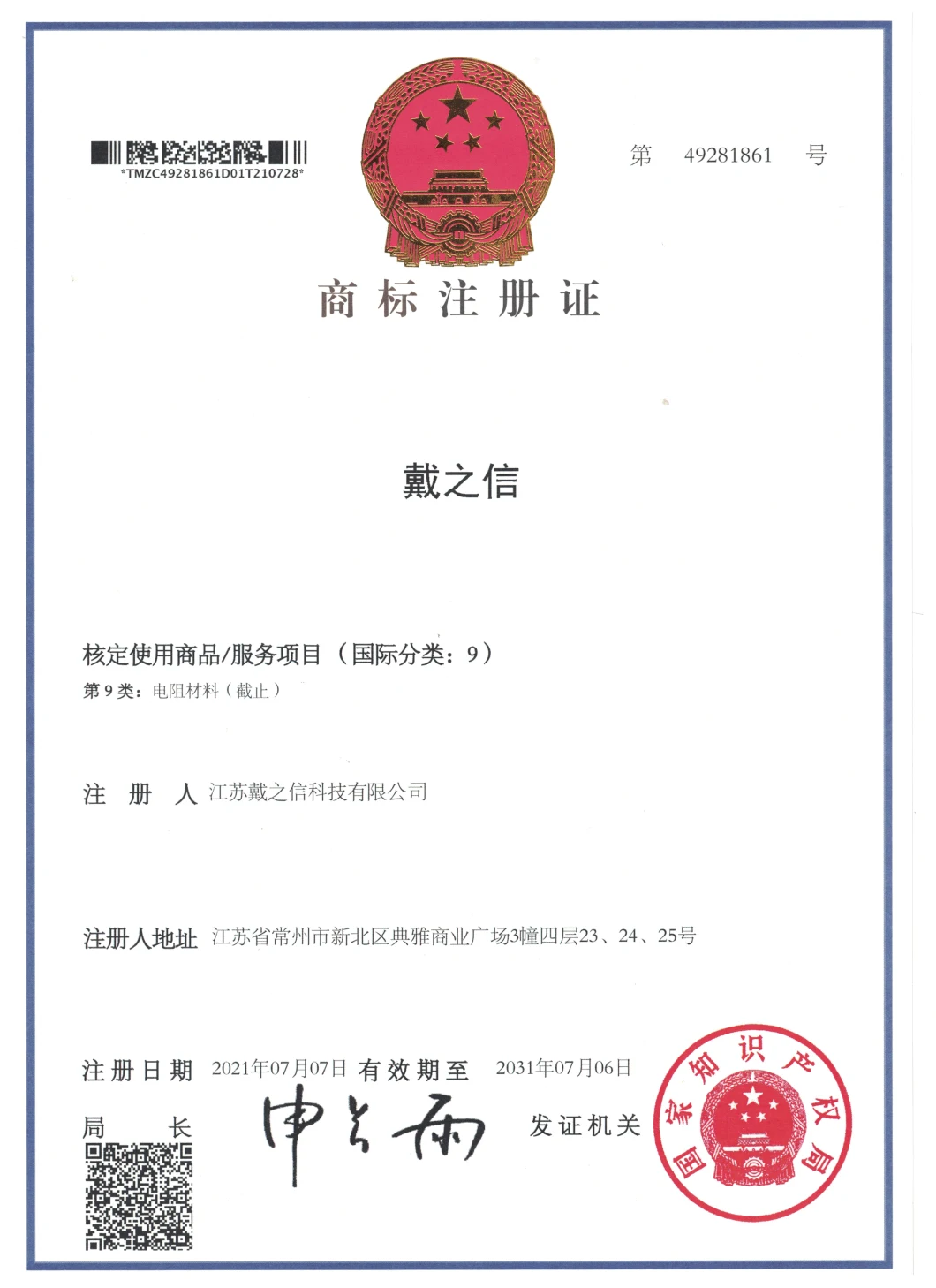

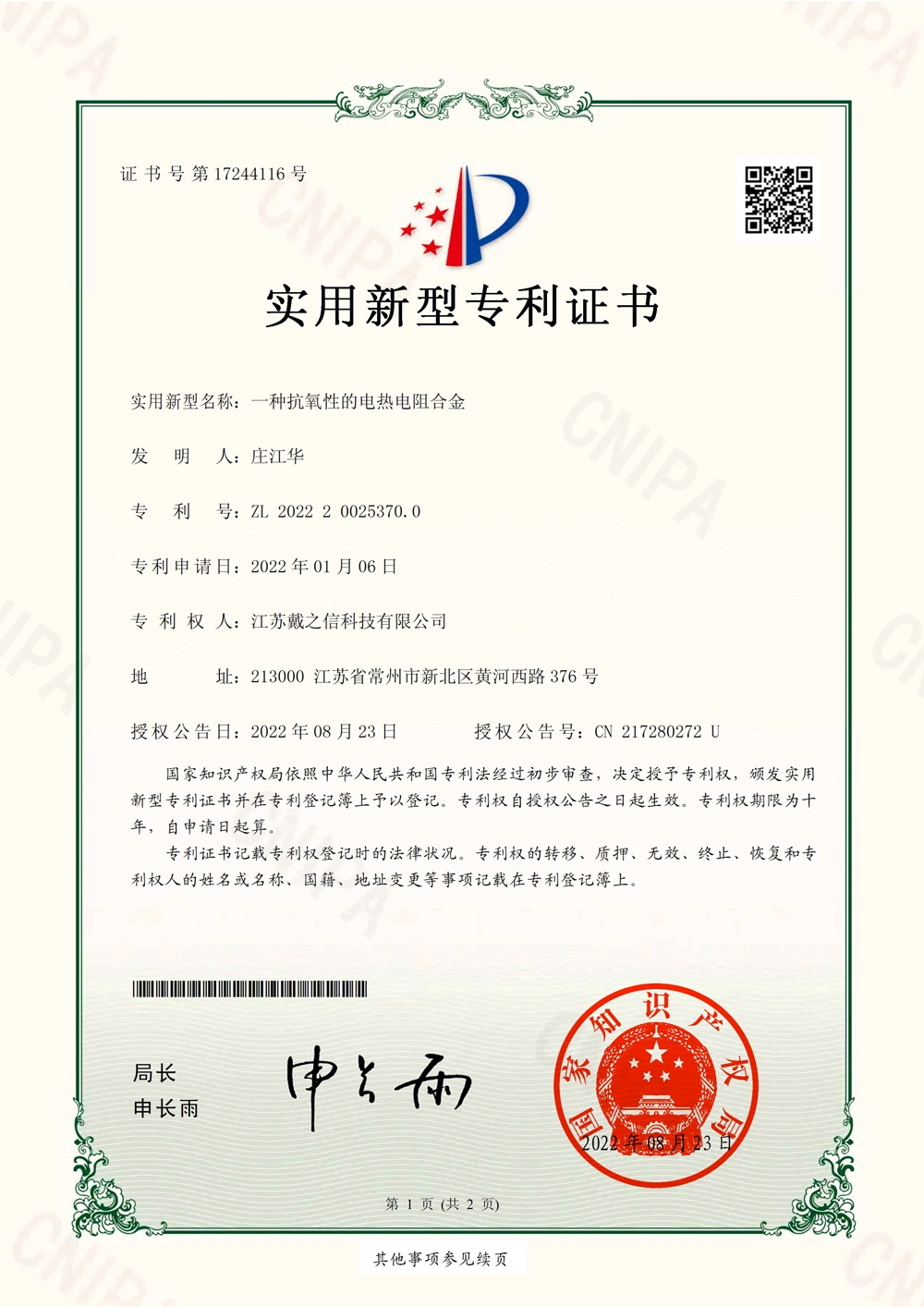

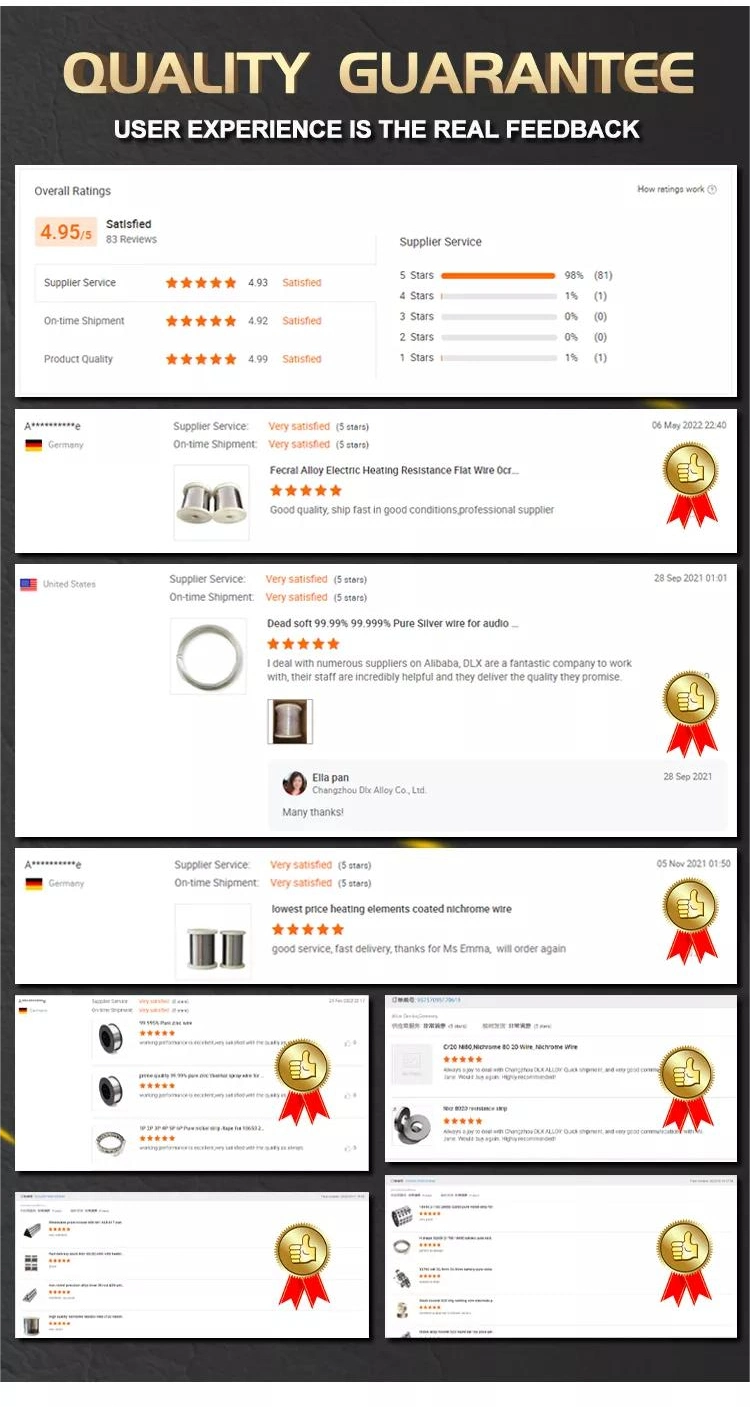

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate 1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy. Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

Question1: Are you a trading company or manufacturer? Answer: We're manufacturer. Question2: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question3: Could you supply samples? Answer: Yes, wecould supply samples according to your requirement. Question4: could we visit your factory? Answer: Sure, factory visit is warmly welcome.| Nickel: | 52 Balance |

| Cobalt: | 1 max. |

| Iron: | 19 |

| Chromium: | 18 |

| Niobium* + Tantalum | 5 |

| Molybdenum: | 3 |

| Manganese: | 0.35 max. |

| Silicon: | 0.35 max. |

| Titanium: | 0.9 |

| Aluminum: | 0.5 |

| Carbon: | 0.05 |

| Boron: | 0.004 |

| Tensile Strength (σb/MPa) | Yield Strength (σp0.2/MPa) | Elongation (σ5/%) |

| 966 | 549 | 30 |

nconel 718 alloy is readily welded by Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), Shielded Metal Arc Welding (SMAW), Electron Beam (EB) and resistance welding techniques. Its welding characteristics are similar to those for HASTELLOY® X alloy. Submerged Arc Welding (SAW) and oxyacetylene are not recommended as these processes are characterized by high heat input to the base metal and slow cooling of the weld. These factors can increase weld restraint and promote cracking.

nconel 718 alloy is readily welded by Gas Tungsten Arc Welding (GTAW), Gas Metal Arc Welding (GMAW), Shielded Metal Arc Welding (SMAW), Electron Beam (EB) and resistance welding techniques. Its welding characteristics are similar to those for HASTELLOY® X alloy. Submerged Arc Welding (SAW) and oxyacetylene are not recommended as these processes are characterized by high heat input to the base metal and slow cooling of the weld. These factors can increase weld restraint and promote cracking. Base Metal Preparation

The welding surface and adjacent regions should be thoroughly cleaned with an appropriate solvent prior to any welding operation. All greases, oils, cutting oils, crayon marks, machining solutions, corrosion products, paint, scale, dye penetrant solutions, and other foreign matter should be completely removed.

Filler Metal Selection

Inconel 718 alloy should be joined using matching filler metal (AWS A5.14 ERNiFeCr-2, AMS5832). For welding 718 alloy to other alloys, HASTELLOY® S (AMS 5838) or W (AWS A5.14 ERNiMo-3, AMS 5786) filler wires are suggested. Please click here or see the Haynes Welding SmartGuide for more information.

Preheating and Interpass Temperatures

Preheat is not required. Preheat is generally specified as room temperature (typical shop conditions). Interpass temperature should be maintained below 200°F (93°C). Auxiliary cooling methods may be used between weld passes, as needed, providing that such methods do not introduce contaminants. For further information, please click here.

Postweld Heat Treatment

Inconel 718 alloy is normally used in the fully-aged condition. Following forming and welding, a full solution anneal prior to aging is often employed in order to develop the best joint and overall fabrication properties. The best practice is dependent upon the specific condition of the fabrication prior to aging. Contact Haynes International, Inc. for further information.

INCONEL alloy 690 (UNS N06690/W. Nr. 2.4642) is a high-chromium nickel alloy having excellent resistance to many corrosive aqueous media and hightemperature atmospheres. In addition to its corrosion resistance, alloy 690 has high strength, good metallurgical stability, and favorable fabrication characteristics. The chemical composition of INCONEL alloy 690 is listed in Table 1. The substantial chromium content gives the alloy outstanding resistance to oxidizing chemicals and to high-temperature oxidizing gases. The high level of nickel imparts resistance to stresscorrosion cracking in chloride-containing environments as well as to sodium hydroxide solutions.