| Item | Inconel 600 | Inconel 601 | Inconel 617 | Inconel 625 | Inconel 690 | Inconel 718 | Inconel X750 | Inconel 825 |

| C | ≤0.15 | ≤0.1 | 0.05-0.15 | ≤0.08 | ≤0.05 | ≤0.08 | ≤0.08 | ≤0.05 |

| Mn | ≤1 | ≤1.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤1 | ≤1 |

| Fe | 6-10 | rest | ≤3 | rest | 7-11 | rest | 5-9 | ≥22 |

| P | ≤0.015 | ≤0.02 | ≤0.015 | -- | -- | -- | -- | -- |

| S | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.015 | ≤0.01 | ≤0.01 | ≤0.03 |

| Si | ≤0.5 | ≤0.5 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.35 | ≤0.5 | ≤0.5 |

| Cu | ≤0.5 | ≤1 | -- | ≤0.3 | ≤0.5 | ≤0.3 | ≤0.5 | 1.5-3 |

| Ni | ≥7.2 | 58-63 | ≥44.5 | 50-55 | ≥58 | 50-55 | ≥70 | 38-46 |

| Co | -- | -- | 10-15 | ≤10 | -- | ≤1 | ≤1 | -- |

| Al | -- | 1-1.7 | 0.8-1.5 | ≤0.8 | -- | 0.2-0.8 | 0.4-1 | ≤0.2 |

| Ti | -- | -- | ≤0.6 | ≤1.15 | -- | -- | 2.25-2.75 | 0.6-1.2 |

| Cr | 14-17 | 21-25 | 20-24 | 17-21 | 27-31 | 17-21 | 14-17 | 19.5-23.5 |

| Nb+Ta | -- | -- | -- | 4.75-5.5 | -- | 4.75-5.5 | 0.7-1.2 | -- |

| Mo | -- | -- | 8-10 | 2.8-3.3 | -- | 2.8-3.3 | -- | 2.5-3.5 |

| B | -- | -- | ≤0.006 | -- | -- | -- | -- | -- |

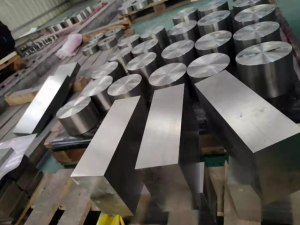

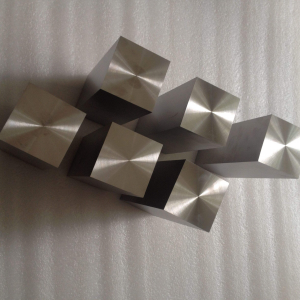

Inconel 600 alloy is a nickel-chromium-iron-based solid-solution strengthened alloy, which has good high temperature corrosion resistance and oxidation resistance, excellent cold and hot processing and welding performance, and has satisfactory thermal strength and high plasticity below 700 °C. chemical composition Ni≥72, Cr14-17, F,6-10, C≤0.15, Mn≤1.0, Si≤0.5, Cu≤0.5 performance Melting temperature range 1370~1430℃ Density ρ=8.43g/cm3 Inconel 625 is an alloy grade with a density of 8.4 g/cm3 and a melting point of 1290-1350°C. It has excellent corrosion resistance to inorganic acids and has excellent corrosion resistance to various corrosive media in oxidizing and reducing environments. Nickel: balance, chromium: 20-23, molybdenum: 8-10, niobium: 3.15-4.15, iron: ≤5, aluminum: ≤0.4, titanium: ≤0.4, carbon: ≤0.1, manganese: ≤0.5, silicon: ≤0.5, cobalt: ≤1, phosphorus: ≤0.015, sulfur: ≤0.015 Mechanical behavior Tensile strength: 827 Rm N/mm Yield strength: 414 RP0.2 N/mm Elongation: 30 A5% Brinell hardness: ≤220 HB Inconel 718 alloy is a precipitation-hardening nickel-chromium-iron alloy containing niobium and molybdenum. It has high strength, good toughness and corrosion resistance in high and low temperature environments below 650 °C. Density ρ=8.24g/cm3 Melting temperature range 1260~1320℃ chemical composition Ni50-55, 17-21Cr, Fe rest, C≤0.08, Mn≤0.35, Si≤0.35, Mo2.8-3.3, Cu≤0.3, Co≤1.0, Al0.2-0.8, Ti0.65-1.15, Nb4 .75-5.5, B≤0.006, P≤0.01, S≤0.01 Similar grades GH4169, GH169 (China), NC19FeNb (France), NiCr19Fe19Nb5, Mo3 (Germany), NA 51 (UK) Inconel718, UNS NO7718 (USA) NiCr19Nb5Mo3 (ISO)

Inconel 600 alloy is a nickel-chromium-iron-based solid-solution strengthened alloy, which has good high temperature corrosion resistance and oxidation resistance, excellent cold and hot processing and welding performance, and has satisfactory thermal strength and high plasticity below 700 °C. chemical composition Ni≥72, Cr14-17, F,6-10, C≤0.15, Mn≤1.0, Si≤0.5, Cu≤0.5 performance Melting temperature range 1370~1430℃ Density ρ=8.43g/cm3 Inconel 625 is an alloy grade with a density of 8.4 g/cm3 and a melting point of 1290-1350°C. It has excellent corrosion resistance to inorganic acids and has excellent corrosion resistance to various corrosive media in oxidizing and reducing environments. Nickel: balance, chromium: 20-23, molybdenum: 8-10, niobium: 3.15-4.15, iron: ≤5, aluminum: ≤0.4, titanium: ≤0.4, carbon: ≤0.1, manganese: ≤0.5, silicon: ≤0.5, cobalt: ≤1, phosphorus: ≤0.015, sulfur: ≤0.015 Mechanical behavior Tensile strength: 827 Rm N/mm Yield strength: 414 RP0.2 N/mm Elongation: 30 A5% Brinell hardness: ≤220 HB Inconel 718 alloy is a precipitation-hardening nickel-chromium-iron alloy containing niobium and molybdenum. It has high strength, good toughness and corrosion resistance in high and low temperature environments below 650 °C. Density ρ=8.24g/cm3 Melting temperature range 1260~1320℃ chemical composition Ni50-55, 17-21Cr, Fe rest, C≤0.08, Mn≤0.35, Si≤0.35, Mo2.8-3.3, Cu≤0.3, Co≤1.0, Al0.2-0.8, Ti0.65-1.15, Nb4 .75-5.5, B≤0.006, P≤0.01, S≤0.01 Similar grades GH4169, GH169 (China), NC19FeNb (France), NiCr19Fe19Nb5, Mo3 (Germany), NA 51 (UK) Inconel718, UNS NO7718 (USA) NiCr19Nb5Mo3 (ISO)

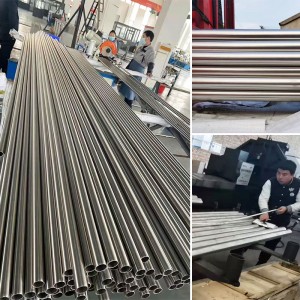

High temperature components, such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines.

High temperature components, such as turbine blades, guide vanes, turbine disks, high pressure compressor disks,machine manufacturing and combustion chambers used in the manufacture of aviation, naval and industrial gas turbines.