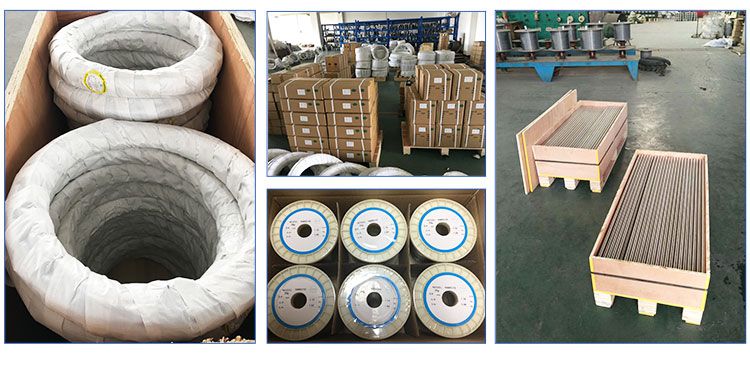

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

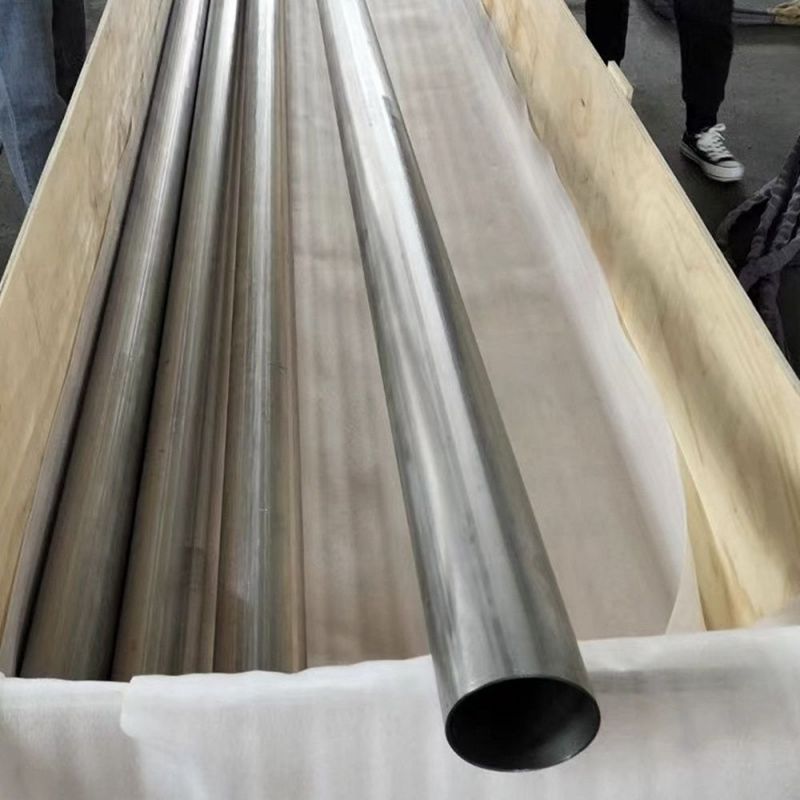

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate Different pure nickel materials are mainly used in chemical, electroplating and electronic fields. Its corrosion resistance has good corrosion resistance in other reducing media except for poor performance in alkaline medium. Compared with nickel base alloy, pure nickel has higher electrical conductivity, thermal conductivity and plasticity. Pure nickel can be processed into products of different shapes The mechanical properties of nickel are close to carbon steel, and its resistance to alkaline corrosion is second only to silver among metal materials. The surface of nickel wire will form a layer of black protective film in concentrated alkali. Make it very resistant to corrosion. Used for electric light source materials, coating, with high surface quality, good processing performance, used for making work such as anode, septa, electrode support, etc., can also be used in the light bulb as a guide wire lead, in addition to the chlor-alkali industry has played a very important role.

Different pure nickel materials are mainly used in chemical, electroplating and electronic fields. Its corrosion resistance has good corrosion resistance in other reducing media except for poor performance in alkaline medium. Compared with nickel base alloy, pure nickel has higher electrical conductivity, thermal conductivity and plasticity. Pure nickel can be processed into products of different shapes The mechanical properties of nickel are close to carbon steel, and its resistance to alkaline corrosion is second only to silver among metal materials. The surface of nickel wire will form a layer of black protective film in concentrated alkali. Make it very resistant to corrosion. Used for electric light source materials, coating, with high surface quality, good processing performance, used for making work such as anode, septa, electrode support, etc., can also be used in the light bulb as a guide wire lead, in addition to the chlor-alkali industry has played a very important role. | CHEMICAL COMPOSITION | |||||||

| Alloy | Ni+Co % | Mn % | Fe % | Si % | Cu % | C % | S % |

| Nickel 201 | Min 99.2 | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.02 | Max 0.01 |

| Nickel 200 | Min | Max 0.35 | Max 0.4 | Max 0.35 | Max 0.25 | Max 0.15 | Max 0.01 |

| 99 | |||||||

| Physical Data | |||||||

| Density | Specific Heat | Electrical Resistivity | Melting Point | Thermal Conductivity | Mean Coeff Thermal Expansion | ||

| 8.89g/cm3 | 0.109(456 J/kg.℃) | 0.096×10-6ohm.m | 1435-1446℃ | 70.2 W/m-K | 13.3×10-6m/m.℃ | ||

| Typical Mechanical Properties | |||||||

| Mechanical Properties | Tensile Strength | Yield Strength | Elongation | Standard | |||

| Nickel 200 | 462 Mpa | 148 Mpa | 47% | ASTM B161/B163/B725/B751 | |||

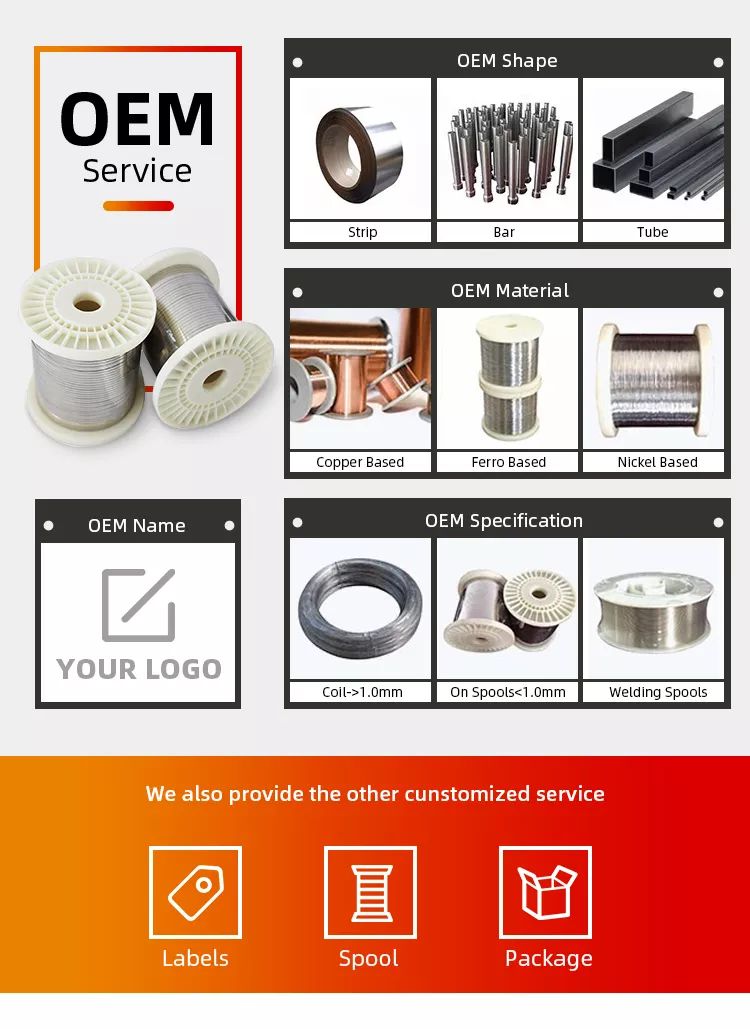

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, We can provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.Ni200 Ni201 is extremely resistance to caustic alkalies up to and including the molten state. The extra-low carbon content of Alloy 200/201 gives virtual immunity to intergranular attack above about 315°C. The presence of chlorates must be kept to aminimum, as they accelerate the rate of attack. Good resistance to corrosion in acids and alkalis and is most useful under reducing conditions. Outstanding resistance to caustic alkalis up to and including the molten state. In acid, alkaline and neutral salt solutions the material shows good resistance, but in oxidizing salt solutions severe attack will occur. Resistant to all dry gases at room temperature and in dry chlorine and hydrogen chloride may be used in temperatures up to 550C. Resistance to mineral acids varies according to temperature and concentration and whether the solution is aerated or not. Corrosion resistance is better in de-aerated acid.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, We can provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.Ni200 Ni201 is extremely resistance to caustic alkalies up to and including the molten state. The extra-low carbon content of Alloy 200/201 gives virtual immunity to intergranular attack above about 315°C. The presence of chlorates must be kept to aminimum, as they accelerate the rate of attack. Good resistance to corrosion in acids and alkalis and is most useful under reducing conditions. Outstanding resistance to caustic alkalis up to and including the molten state. In acid, alkaline and neutral salt solutions the material shows good resistance, but in oxidizing salt solutions severe attack will occur. Resistant to all dry gases at room temperature and in dry chlorine and hydrogen chloride may be used in temperatures up to 550C. Resistance to mineral acids varies according to temperature and concentration and whether the solution is aerated or not. Corrosion resistance is better in de-aerated acid.