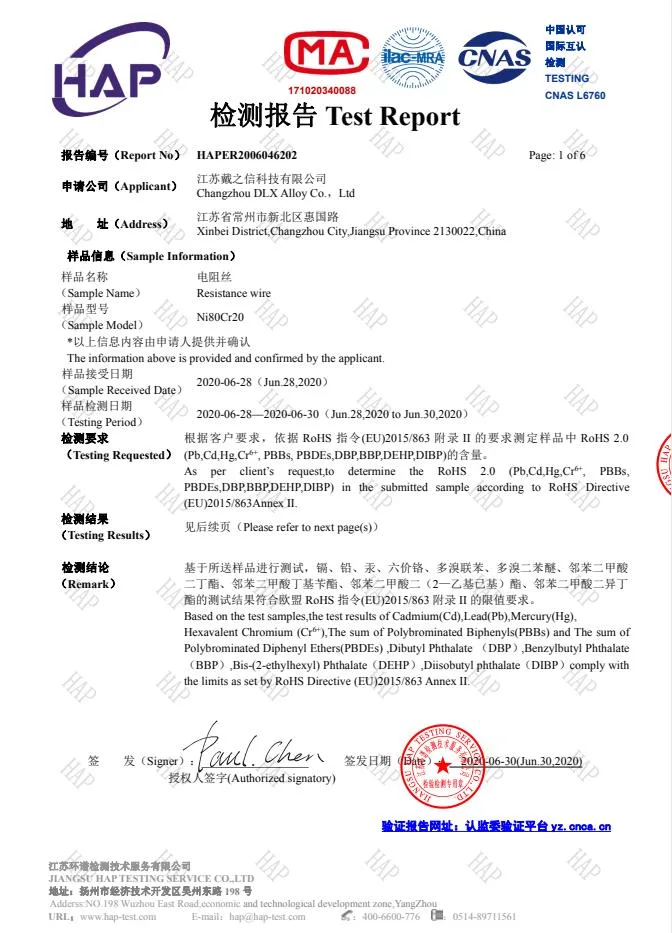

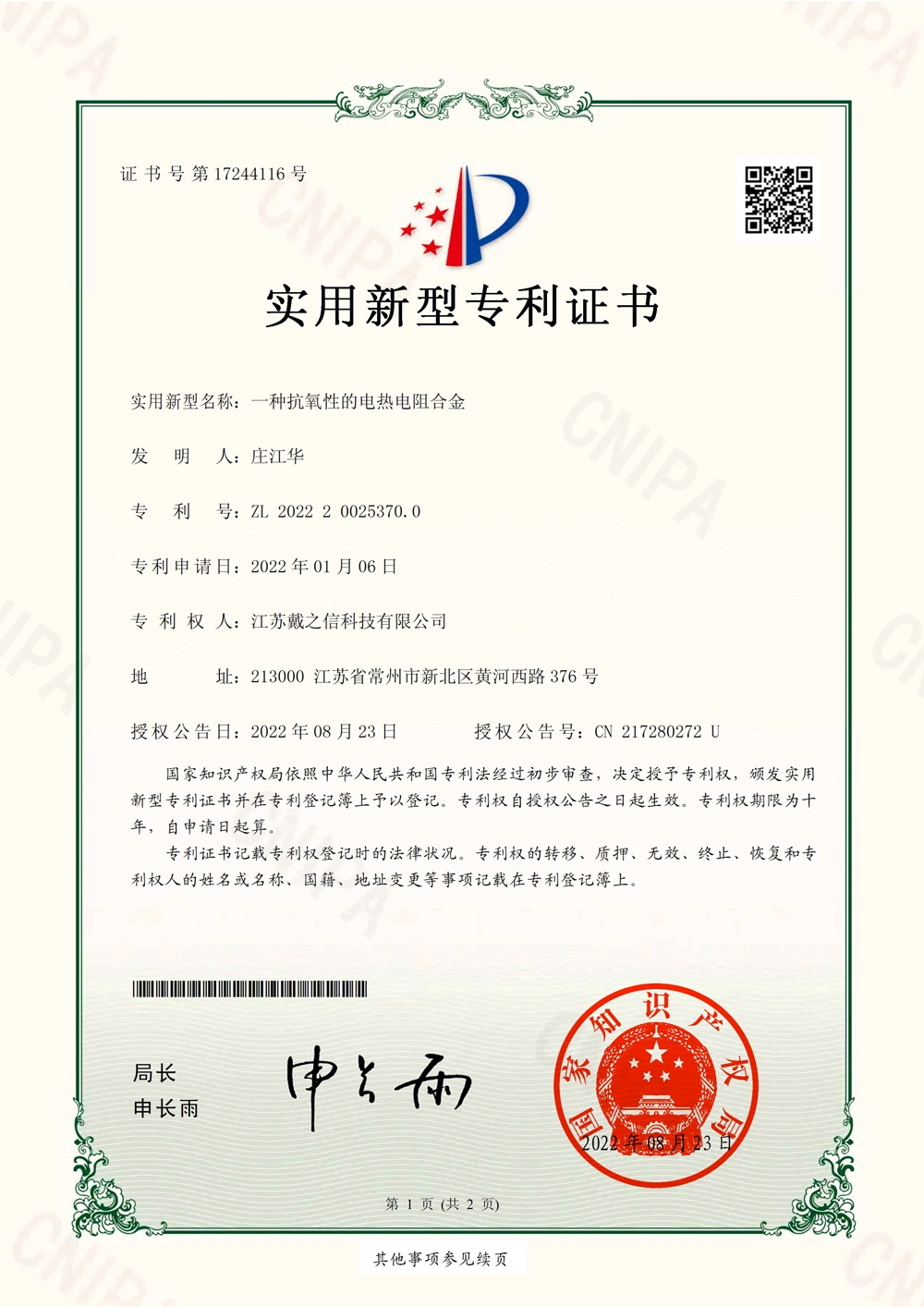

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate 1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.Inconel 625 wire alloy can be made in flat, square, or even shaped wires. When you begin to analyze it, the two things that immediately stand out are its resistance to oxidation and its scaling at very high temperatures. This makes it vastly superior to other alloys, even ones that are made for high temperatures and varying heating and cooling conditions. The makeup of Inconel 625 wire also makes it able to withstand corrosive environments as well, even severe ones. In fact, there is almost no impact on the wire in fresh or even salt water. This also holds true for non-acidic environments as well. The high levels of Molybdenum also allows the alloy to be very resistant to pitting.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, Wecan provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.Inconel 625 wire alloy can be made in flat, square, or even shaped wires. When you begin to analyze it, the two things that immediately stand out are its resistance to oxidation and its scaling at very high temperatures. This makes it vastly superior to other alloys, even ones that are made for high temperatures and varying heating and cooling conditions. The makeup of Inconel 625 wire also makes it able to withstand corrosive environments as well, even severe ones. In fact, there is almost no impact on the wire in fresh or even salt water. This also holds true for non-acidic environments as well. The high levels of Molybdenum also allows the alloy to be very resistant to pitting.Nominal Composition

Ni: 58.0 min Cr: 20.0 – 23.0 Mo: 8.0 – 10.0 Cb (Nb): 3.15 – 4.15 Fe: 5.0 max Co: 1.0 max Si: 0.5 max Mn: 0.5 max Al: 0.4 max Ti: 0.4 max C: 0.10 maxPhysical Properties

Density: 0.305 lb/in3, (8.44 g/cm3) Modulus of Elasticity (E): At 70°F (20°C): 30.1 x 103 ksi (208 GPa) Modulus of Rigidity (G): At 70°F (20°C): 11.8 x 103 ksi (81.2 GPa) Coefficient of Expansion: 7.4 µin/in.-°F (70°F to 600°F) 13.3 µm/m-°C (20°C to 300°C) Electrical Resistivity: 50.8 µΩ.in, (129 µΩ.cm) Thermal Conductivity: 68 Btu-in/ft2hr-°F, (9.8 W/m-K)Typical Mechanical Properties – Spring Applications

- Annealed

- Heat Treatment: 1925°F (1050°C)

- Tensile Strength: 120 – 150 ksi; (830-1100 MPa)

- Suggested Operating Conditions: -300°F to 700°F (-184°C to 370°C)

- Spring Temper

- Tensile Strength: 200 – 240 ksi; (1380 – 1655 MPa)

- Suggested Operating Conditions: -300°F to 700°F (-184°C to 370°C)