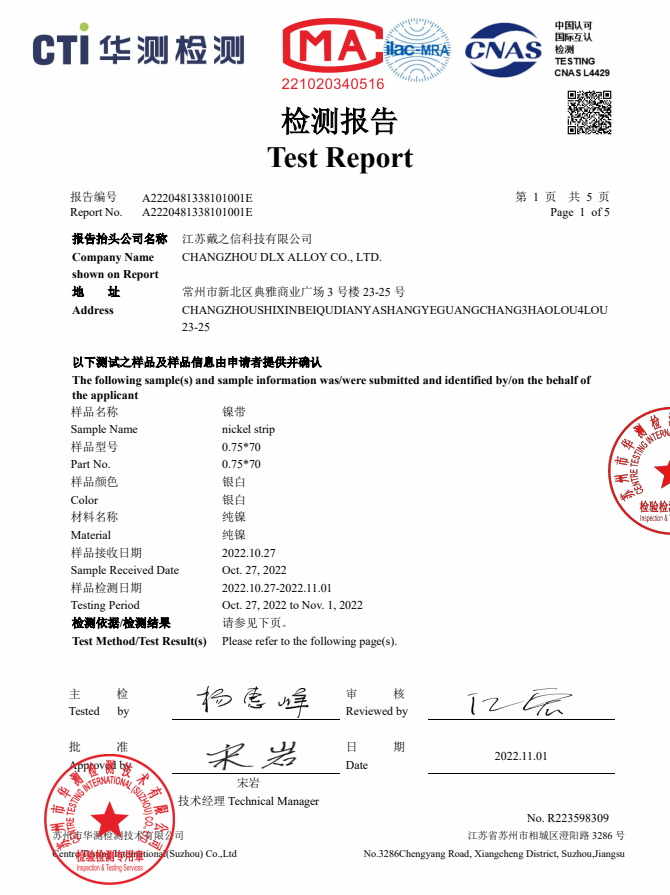

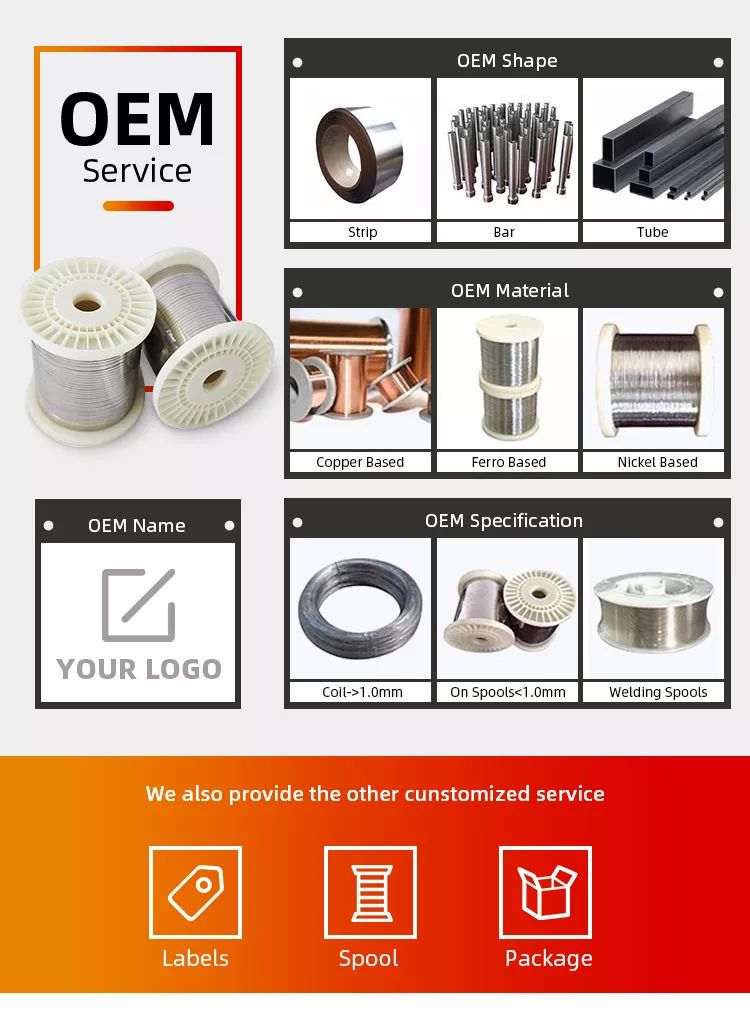

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, We can provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

1, We're able to design and develop the product what our customers require and meet their requirements through providing the appropriate engineering drawings or samples. 2, We can provide the products within a week after payment. 3, We can provide sample of the products customer need. 4, We always insist on "Quality first, Customer first" as our business philosophy.Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

| Grade | Ni+Co | Cu | Si | Mn | C | Mg | S | P | Fe |

| N4 | 99.8 | 0.015 | 0.03 | 0.002 | 0.01 | 0.01 | 0.001 | 0.001 | 0.04 |

| N6 | 99.6 | 0.10 | 0.10 | 0.05 | 0.10 | 0.10 | 0.005 | 0.002 | 0.10 |

| Ni201 | ≥99.0 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.02 | / | ≤0.01 | / | ≤0.40 |

| Ni200 | ≥99.2 | ≤0.25 | ≤0.35 | ≤0.35 | ≤0.15 | / | ≤0.01 | / | ≤0.40 |

| Physical Data | |

| Density | 8.89g/cm3 |

| Specific Heat | 0.109(456 J/kg.ºC) |

| Electrical Resistivity | 0.096×10-6ohm.m |

| Melting Point | 1435-1446ºC |

| Thermal Conductivity | 70.2 W/m-K |

| Mean Coeff Thermal Expansion | 13.3×10-6m/m.ºC |

| Typical Mechanical Properties | |

| Mechanical Properties | Nickel 200 |

| Tensile Strength | 462 Mpa |

| Yield Strength | 148 Mpa |

| Elongation | 47% |

| Our Production Standard | |||||

|

| Bar | Forging | Pipe | Sheet/Strip | Wire |

| ASTM | ASTM B160 | ASTM B564 | ASTM B161/B163/B725/B751 | AMS B162 | ASTM B166 |

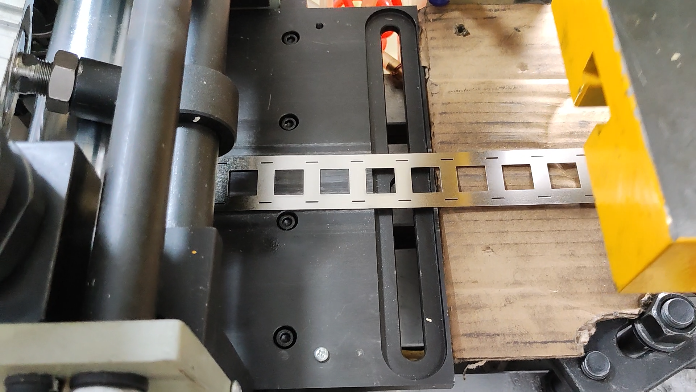

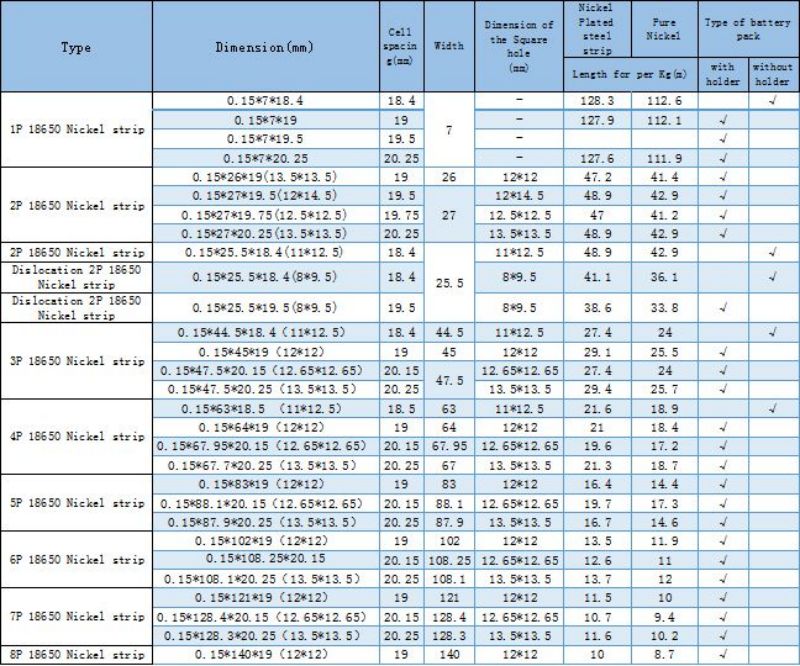

1. Low resistance, make the battery pack more powerful, save energy. 2. Pure Nickel to make it easy welding, stable connection 3. Dood tensile and easy operate assembly. 4. shaped design, save too much work for customer to assembly battery pack. 5. High Electrical Conductivity 6. Anti-corrosive and low resistance

1. Low resistance, make the battery pack more powerful, save energy. 2. Pure Nickel to make it easy welding, stable connection 3. Dood tensile and easy operate assembly. 4. shaped design, save too much work for customer to assembly battery pack. 5. High Electrical Conductivity 6. Anti-corrosive and low resistance 1. Widely used in electronic products, is the first choice for making resistance element material 2. Pure nickel wire as electric vacuum material has good processing performance, strong welding(fusion welding, brazing welding),can be used for electroplating . 3. And can be used to produce such as corrosion resistance strong electron tube, bulbs, fluorescent lamp, anode, spacers, electrode holder, lighting, radio equipment, weaving nets, chemical, petroleum, power, aviation, Marine development and environmental protection, etc. battery connection and extraction, the products are mainly used in nickel-metal hydride batteries, lithium batteries, tabs, power tools, assembled batteries, polymer batteries, power batteries and instrumentation, telecommunications, electric vacuum, special light bulbs , lithium batteries, high magnification power tools batteries, laptop batteries, battery combination with HM and other industries.For different batteries, the poles' materials would be different. Most of them are made of stainless steel, iron-plated nickel or iron. In terms of the degree of weldability, stainless steel > iron-plated nickel > iron, which means a 0.15 mm pure nickel sheet can be welded to a battery’s pole made of stainless steel easier than a pole made of iron. Lithium-ion cells are made in various sizes, often assembled into packs for portable electrical tools. Most battery packs also include a BMS to prevent over-charge, over-discharge and short-circuit damage. You also need to prepare a specific charger for your lithium-ion battery pack.

1. Widely used in electronic products, is the first choice for making resistance element material 2. Pure nickel wire as electric vacuum material has good processing performance, strong welding(fusion welding, brazing welding),can be used for electroplating . 3. And can be used to produce such as corrosion resistance strong electron tube, bulbs, fluorescent lamp, anode, spacers, electrode holder, lighting, radio equipment, weaving nets, chemical, petroleum, power, aviation, Marine development and environmental protection, etc. battery connection and extraction, the products are mainly used in nickel-metal hydride batteries, lithium batteries, tabs, power tools, assembled batteries, polymer batteries, power batteries and instrumentation, telecommunications, electric vacuum, special light bulbs , lithium batteries, high magnification power tools batteries, laptop batteries, battery combination with HM and other industries.For different batteries, the poles' materials would be different. Most of them are made of stainless steel, iron-plated nickel or iron. In terms of the degree of weldability, stainless steel > iron-plated nickel > iron, which means a 0.15 mm pure nickel sheet can be welded to a battery’s pole made of stainless steel easier than a pole made of iron. Lithium-ion cells are made in various sizes, often assembled into packs for portable electrical tools. Most battery packs also include a BMS to prevent over-charge, over-discharge and short-circuit damage. You also need to prepare a specific charger for your lithium-ion battery pack.