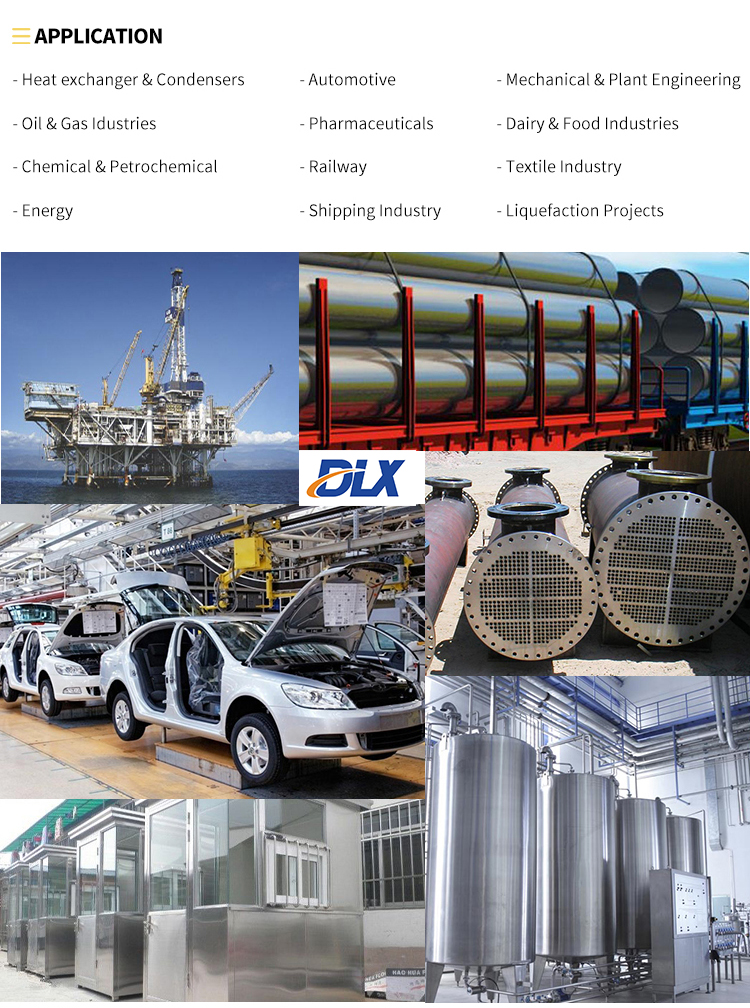

An alloy is a material with advancing characteristics formed by fusing a metal element and one or several other elements (either metal or non-metal). The most basic substance that makes up an alloy and can exist independently is called a component, or element for short. In most cases, the components are the elements that make up the alloy. However, there are also compounds that are used as components, and the condition is that the compound neither decomposes nor undergoes any chemical reactions within the scope of the study. According to the number of components, it can be divided into binary alloys, ternary alloys or multi-component alloys. For example, simple brass is a binary alloy composed of two elements: copper and zinc; duralumin is composed of three elements: aluminum, copper, and magnesium. composed of ternary alloys. Copper and nickel can be infinitely dissolved in each other to form a continuous solid solution, that is, regardless of the ratio of each other, it is always an α-single-phase alloy. When nickel is melted into red copper D200, when the content exceeds 16%, the color of the resulting alloy becomes relatively white like silver. The higher the nickel content, the whiter the color. 70%, the naked eye will see the yellow color of copper. What's more, the content of nickel in cupronickel is generally 25%. Cupronickel is an elegant name for copper-nickel alloy, and its density is 8.9-8.88 between copper and nickel.Pure copper plus nickel can significantly improve strength, corrosion resistance, hardness, electrical resistance and pyroelectricity, and reduce the temperature coefficient of resistivity. Therefore, the mechanical and physical properties of white copper are exceptionally better than other copper alloys. Good ductility, high hardness, beautiful color, corrosion resistance and deep drawing performance, are widely used in shipbuilding, petrochemical, electrical appliances, instruments, medical machinery, daily necessities, handicrafts and other fields, and are also important resistance and thermocouple alloys. The disadvantage of cupronickel is the main added element - nickel is a scarce strategic material, and the price is relatively expensive.New material high quality Using the best new copper material, refuse to use scrap recovery material. Precise, Smooth and Tidy Our material size is precise and surface smooth and flat. Cutting edge tidy and no burr. Professional customized We can customize width,length and thickness. We also have mass stock for standard size.CuNi1,CuNi2,CuNi6,CuNi8,CuNi10,CuNi14,CuNi19,CuNi23,CuNi30,CuNi44 Constantan 6J40,6J11, Manganin:6J12,6J13,6J8

An alloy is a material with advancing characteristics formed by fusing a metal element and one or several other elements (either metal or non-metal). The most basic substance that makes up an alloy and can exist independently is called a component, or element for short. In most cases, the components are the elements that make up the alloy. However, there are also compounds that are used as components, and the condition is that the compound neither decomposes nor undergoes any chemical reactions within the scope of the study. According to the number of components, it can be divided into binary alloys, ternary alloys or multi-component alloys. For example, simple brass is a binary alloy composed of two elements: copper and zinc; duralumin is composed of three elements: aluminum, copper, and magnesium. composed of ternary alloys. Copper and nickel can be infinitely dissolved in each other to form a continuous solid solution, that is, regardless of the ratio of each other, it is always an α-single-phase alloy. When nickel is melted into red copper D200, when the content exceeds 16%, the color of the resulting alloy becomes relatively white like silver. The higher the nickel content, the whiter the color. 70%, the naked eye will see the yellow color of copper. What's more, the content of nickel in cupronickel is generally 25%. Cupronickel is an elegant name for copper-nickel alloy, and its density is 8.9-8.88 between copper and nickel.Pure copper plus nickel can significantly improve strength, corrosion resistance, hardness, electrical resistance and pyroelectricity, and reduce the temperature coefficient of resistivity. Therefore, the mechanical and physical properties of white copper are exceptionally better than other copper alloys. Good ductility, high hardness, beautiful color, corrosion resistance and deep drawing performance, are widely used in shipbuilding, petrochemical, electrical appliances, instruments, medical machinery, daily necessities, handicrafts and other fields, and are also important resistance and thermocouple alloys. The disadvantage of cupronickel is the main added element - nickel is a scarce strategic material, and the price is relatively expensive.New material high quality Using the best new copper material, refuse to use scrap recovery material. Precise, Smooth and Tidy Our material size is precise and surface smooth and flat. Cutting edge tidy and no burr. Professional customized We can customize width,length and thickness. We also have mass stock for standard size.CuNi1,CuNi2,CuNi6,CuNi8,CuNi10,CuNi14,CuNi19,CuNi23,CuNi30,CuNi44 Constantan 6J40,6J11, Manganin:6J12,6J13,6J8| Shape | Size(mm) |

| Wire | 0.08-7.5 |

| Bar | 8.0-50 |

| Ribbon | (0.05-0.35)*(0.5-6.0) |

| Strip | (0.5-2.5)*(5-180) |

| Properties | Resistivity (200C μΩ.m) | Tensile Strength (Mpa) | Max Working Temperature(℃) | Density (g/cm3) |

| CuNi1 | 0.03 | 210 | 200 | 8.9 |

| CuNi2 | 0.05 | 220 | 200 | 8.9 |

| CuNi6 | 0.1 | 250 | 220 | 8.9 |

| CuNi8 | 0.12 | 270 | 250 | 8.9 |

| CuNi10 | 0.15 | 290 | 250 | 8.9 |

| CuNi14 | 0.2 | 310 | 300 | 8.9 |

| CuNi19 | 0.25 | 340 | 300 | 8.9 |

| CuNi23 | 0.3 | 350 | 300 | 8.9 |

| CuNi30 | 0.35 | 400 | 350 | 8.9 |

| CuNi34 | 0.4 | 400 | 350 | 8.9 |

| CuNi44 | 0.5 | 420 | 400 | 8.9 |

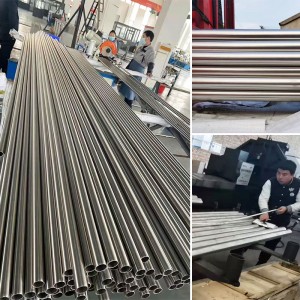

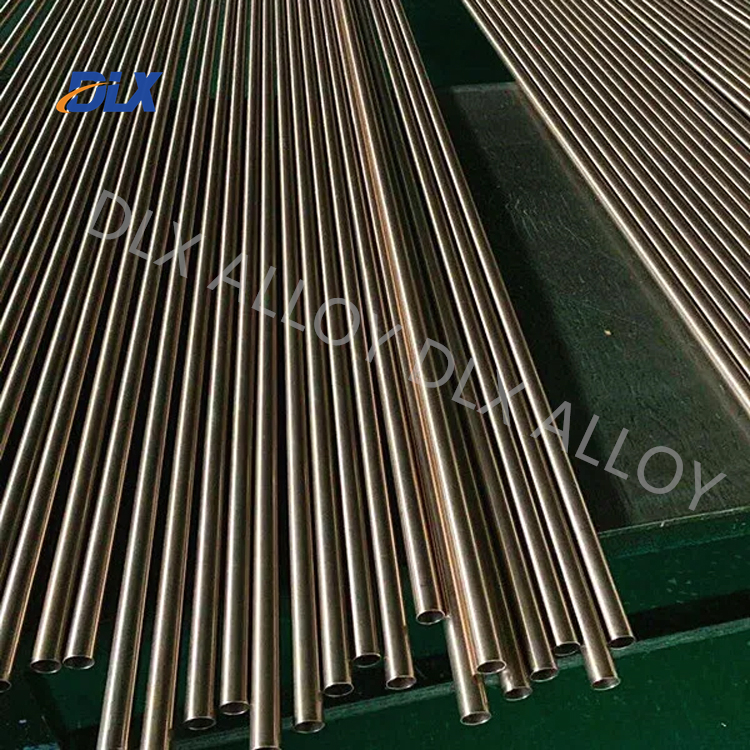

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Our company Principle is " Quality first, Customer first". CHANGZHOU DLX ALLOY CO, LTD was established in 2002 and has got Iso9001 International Quality Management System Certificate and SGS Certificate. Our factory is professional in researching and producing special alloy material. From melting, drawing, heat treatment, finishing and testing .We offer nickel-based, copper-based, and iron-based alloys, including super alloy, welding materials, anti-corrosion alloy, precision alloy, FeCrAl alloy, NiCr alloy, CuNi alloy, thermocouple and Foam Metal etc, in the form of wire, strip, ribbon, bar, tube, plate

Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.

Question1: How can I contact with your company? Answer: We are always ready to serve you via Email, Telephone, Fax, Skype, Whatsapp or Mobile telephone. Tel:+86-18961220953 Skype:18961220953(Steven dlx) Whatsapp: +86-18961220953 Email:sales10@dlx-alloy.com Question2: Are you a trading company or manufacturer? Answer: We're manufacturer. Question3: Could you help to design the product? Answer: Yes, we have excellent R&D team, OEM/ODM orders are all welcome. Question4: Could you supply samples? Answer: Yes, we could supply samples according to your requirement. Question5: could we visit your factory? Answer: Sure, factory visit is warmly welcome.